- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

As precision manufacturing becomes more and more important, the call for high-performance tooling solutions echoes ever louder in the industry. According to a new industry report by Market Research Future, the global precision manufacturing market is likely to amount to about $659 billion by 2025 on advances in technologies as well as increasing demands on very high precision components. Some of the innovations currently making waves within the industry include the Heavy Duty Angle Head tool, which enables an even larger degree of flexibility and accuracy in machining operations. These specialty attachments enable manufacturers to easily handle complex geometries and multi-directional machining operations, thereby improving productivity and decreasing cycle times.

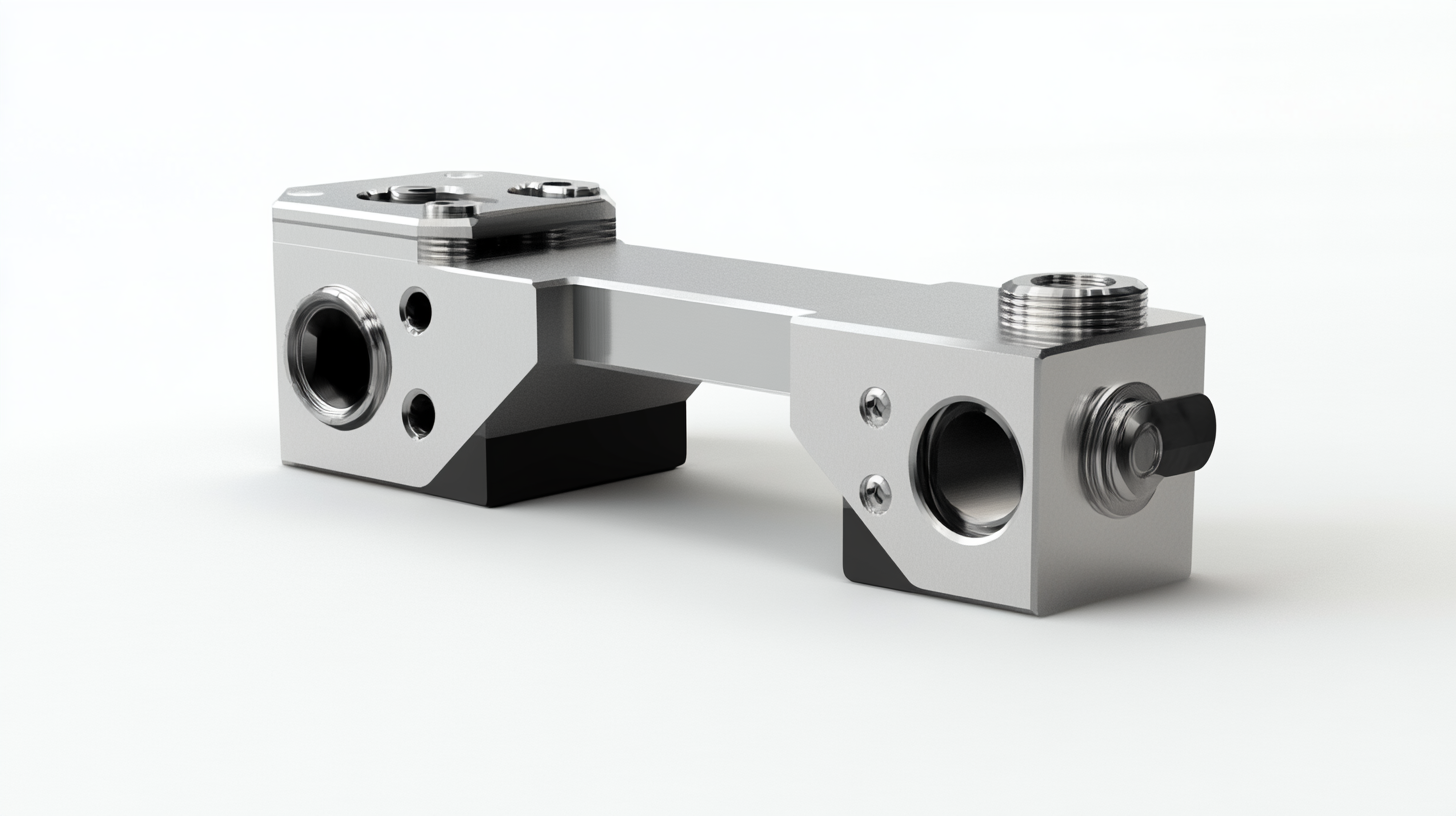

Founded in 2011, Beijing BOD Technology Co., Ltd. is one of the technology companies delivering essential peripheral accessories and ancillary materials for precision manufacturing. We provide Heavy Duty Angle Heads and more of other such accessories for the even-stricter modern demands for machining. In practice, we provide our clients with making tools through our quality and innovation edge. And as the industry expands, establishment of Heavy Duty Angle Heads shall, besides revolutionizing the possibilities of machining, also offer a paradigm shift towards a more intelligent and precise manufacturing process.

Lately, the heavy-duty angle heads turned out to be very useful one in precision manufacturing as they have various features for improving the efficiency and accuracy of end operations. The increase rigidity feature makes the angle heads more precise when machining very complex geometries due to very little vibrations at tool close contact with the workpiece. Thus, enabling finest tolerances for any manufacturer in the domestic and structural application parts because it is very critical in the aerospace and automotive industry, where precision is paramount. In addition, a heavy-duty angle head grants another significant capability: multi-directional machining and access to otherwise inaccessible difficult angles and locations to standard tools. Thus, it expands greatly the manufacturing capabilities. The efficiency not only boosts workflow but also reduces secondary processes, making it a more economical operation to the overall production facility. Setups change less often where the operator can execute complex designs within setups over and over again, saving time and costs in the long run. The heavy duty angle heads now have incorporated good state-of-the-art cooling systems that will keep optimal temperatures in the cutting tool during operation. This is necessary to minimize wear from the cutting tool and very important to keep up the performance consistency for long periods. It has thus led manufacturers to be sure of these tools getting into longer production runs without compromising on quality, thus leading to a very efficient and cost-effective manufacturing operation.

In the world of precision manufacturing, machining precision becomes paramount. One of the leading advancements to machining precision is utilization of heavy-duty angle heads. Angle heads are known to increase CNC machine efficiency by nearly 30%, and therefore, the more complex part geometries can be realized without sacrificing operational efficiency. In that way, these angle heads permit multi-axis machining, thus enabling manufacturers to achieve precision levels consistent with the manufacturers.

Heavy-duty angle heads are built to withstand high loads without losing stability, whether these fancy materials are handled or even with complex geometric designs. Implementation of these heavy-duty tooling systems has caused a 20% increase in tool life, according to the American Society of Mechanical Engineers. This durability ensures that the precision attained is maintained throughout the machining cycle, reducing downtime and the number of tool changes.

Moreover, with the ability to reach difficult workpiece angles without rerotation of the workpiece, a significant improvement is created in cycle time reduction. This amount of flexibility might create a decrease in labor costs, as operators spend less actual time with the set-up of the workpiece and more hands-on time running the production machines. Hence, manufacturers adopting businesses of heavy-duty angle heads are likely to capitalize on increased efficiencies, thus enhancing productivity and providing the precision in machining, which customers now demand in the competitive environment.

Currently in the age of competition, adaptation and performance of machines affect operation efficiency and output quality. Heavyweight angle heads are verging on becoming the revolutory in this industry as these are taking up speed around giving maximum versatility to allow manufacturers to handle several applications. The international market for angle heads is expected to grow over 5% annually due to advancements in manufacturing technologies and the increasing demand for precision engineering.

Heavy-duty angle heads can be adapted to tackle specific tasks, including milling, drilling, and grinding, both in different materials and possible operations. Consequently, this adds to efficiency and reduces the multitude of machines needed, thus saving on both time and space for production. So for an example, an organization's manufacturing department does not need to halt production for long periods before switching from one operation to another; in this way, they save time and ensure highly productive work environments, particularly under tight deadlines.

In addition, heavy-duty angle heads are quite capable of withstanding a wide range of demanding applications, thus ensuring smooth performance. Most manufacturers using these tools have reported efficiency increases of as much as 20 percent, proving that they have a significant impact on a production process. This is particularly true in industries where precision cannot be compromised, such as aerospace and automotive industries, where even millimeters can change the quality of the end product. In fact, one might say that the future of manufacturing will continually be improved by new ways forward, such as heavy-duty angle heads, into greater precision and capability for producing high-quality products.

Heavy-duty angle heads zoomed in on manufacturing as the essential tool for precision applications to the end user owing to cycle-time reduction and improved efficiency. This angle head easily allows to run several operations without resetting the workpiece, while certainly smoothening and reducing delays in operations even further through process streamlining and producing massive time savings.

Heavy duty angle heads reduce a lot of possible time for tool changing or machine setup when it comes to the multiplicity that they would otherwise bring into the requirement of a more complex geometry processed in a one-off condition. This way, the whole amount of processes is reduced and, thus directly, cycle time becomes shorter and thus orders are qualified faster, and with even more agility, they could respond to market demand. In a world that emphasizes every second in the clock, heavy-duty angle heads reduce cycle times so that they become much more directed towards high throughput and improved productivity.

Again, with professionalism, industries are held accountable for optimizing operations, costs, thereby making investment in the angle heads a wise move. Most precision and consistency in production lines will ensure the production of quality end products at the shortest possible time. Therefore, using heavy-duty angle heads is no longer a matter of choice by precision manufacturers only, but it is an evolution that is inevitable for them to use in meeting modern manufacturing demands.

Optimizing options for the angle head is extremely important because all the work is being done in precision manufacturing. Heavy-duty angle heads can hold up to intense machining operations while retaining accuracy. But not all angle heads are built the same way; the choice of materials has a major impact on the functionality of the angle head and its life. If you choose an angle head made of the right materials, you will be able to optimize performance while adding to the life of the angle head.

High-strength steel and aluminum alloys are the common materials used in the making of heavy-duty angle heads. High-strength steel offers stiffness and resistance to wear, making it suitable for heavy machining jobs. Aluminum alloys are better lightweight options, which to some extent can promote faster machining speeds, thus cutting down cycle times. When it comes to angle heads, consideration must be given to specific demands of the project in question, including the type of materials being machined and the required tolerances.

In addition to materials, some other surface treatments and coatings may work towards enhancing the angle head performance. Hard coatings, for example, can resist wear, while a variety of specialized finishes can reduce friction and assure smoother operation. Considerations about the materials and treatments chosen will go a long way to enhance precision and productivity in your manufacture processes and ultimately lead to the success of your projects.

Conversely, there is no denying that the angle heads are indispensable to precision manufacturing. These cutting-edge tools encompass so many advantages that they have become an integral part of achieving superior machining results on the workpiece. But to get the maximum benefit, there is nothing like regular maintenance. Well, regular maintenance and good operational handling can prolong the lifespan of this equipment.

It is important for the user to always check and clean the bearing surfaces and the coolant passages regularly; because they would clog up due to debris or coolant squirted in on operations, leading to inefficient operation and a bit more wear. Adding to this, always keep angle heads properly lubricated according to the manufacturer's specifications. This decreases friction and heat, which usually leads to premature wear.

Calibration is also another important maintenance practice. Periodic checks on the angle heads should be done to check their precision and alignment. If compared with the process and the working environment, proper maintenance of these wonderful tools would mean long-lasting productivity and efficiency in a manufacturing environment, which include expensive maintenance costs. In this way, maintenance would save very costly downtimes from the companies and the inevitable performance of heavy-duty angle heads.

In precision manufacturing, heavy-duty angle heads truly have turned the tables in favor of efficiency and accuracy. Take, for instance, a leading aerospace enterprise that employed heavy-duty angle heads in its machining operations. Incorporation of these specialized attachments enabled cycle time reduction without compromising on quality for highly complex parts used in aircraft assembly. Due to the special capability of angular tool re-orientation, multi-sided machining was accomplished without a need for repositioning the workpiece, thus saving time and costs.

An equally compelling success story unfolds in the automotive industry when a manufacturer faced challenges in producing intricate components with tight tolerances. Integrating heavy-duty angle heads into the CNC milling procedure allowed them to work around the restrictions of conventional methods. With this change, intricate geometries were machined and high precision achieved in a single setup, thereby enhancing their manufacturing process's toughness while ensuring components adhered to high industry standards.

From these real-world applications, one gets a sense of how heavy-duty angle heads are not just fixtures but rather, indispensable tools capable of radically modifying the precision-manufacturing paradigm across industries. From aerospace to automotive, this variety and efficiency offer the ability to enable manufacturers to face increasingly complex designs with assurance.

In the realm of precision manufacturing, heavy-duty angle heads stand out as a transformative tool which promises significant cost-effectiveness together with enhancing performance. As industries continue to evolve, the investment in robust machinery like these angle heads can be justified through comprehensive cost-benefit analysis. One predominant factor to consider is the potential impact on operational efficiency. Heavy-duty angle heads will lessen the need for multiple setups through versatile machining capabilities, thus saving significant time and labor costs—which are indeed crucial in a world of competitive manufacturing.

Moreover, recent trends within various sectors have spotlighted the focus on cost-effectiveness. An illustration of this trend can be seen in data centers: cooling technology is rapidly moving toward liquid cooling, symbolizing a broader paradigm shift in the industry dictated by performance increases while also providing cost savings. A similar line of thought is being extrapolated to precision manufacturing, where the efficiency is assured by smoothened production processes courtesy of heavy-duty angle heads. This, in turn, yields higher output rates with less waste, which implies lower total costs and a stronger bottom line.

Additionally, the return on investment from implementing a heavy-duty angle head is maximized if challenger options for both durability and reliability are judged. As demonstrated in the healthcare and financial arenas, ROI can result from investments that accentuate the tension existing between performance and affordability, taking a long-term view. Organizations that step in for sustenance of the advantages of these heavy-duty angle heads expect further enhancement of their manufacturing capabilities and a hefty competitive edge through smart financial management and resource utilization.

Heavy-duty angle heads are typically constructed from high-strength steel and aluminum alloys, with high-strength steel offering superior rigidity and wear resistance, while aluminum alloys provide a lightweight alternative that enhances machining speeds.

Coatings such as hard coatings improve wear resistance, and specialized surface treatments can reduce friction, leading to smoother operations and enhanced performance of the angle heads during machining.

Choosing the right angle head is crucial for achieving optimal results in precision manufacturing, as it impacts the accuracy, efficiency, and longevity of the machining process.

In the aerospace industry, a leading company utilized heavy-duty angle heads to significantly reduce cycle times and improve the quality of complex parts, allowing for multi-sided machining without repositioning the workpiece.

Heavy-duty angle heads improve operational efficiency by reducing the need for multiple setups, saving time and labor costs, which leads to higher output rates and lower overall manufacturing costs.

By integrating heavy-duty angle heads into machining operations, manufacturers can execute complex geometries and maintain tight tolerances in a single setup, thus improving the robustness and precision of their processes.

The ROI can be maximized through the longevity and reliability of angle heads, leading to enhanced manufacturing capabilities and significant long-term financial benefits for organizations.

Heavy-duty angle heads are transformative tools in various sectors, including aerospace and automotive, enabling manufacturers to tackle complex designs with increased efficiency and confidence.

Heavy-duty angle heads help overcome limitations of traditional machining methods, allowing manufacturers to achieve high precision and efficiency in producing intricate components with tight tolerances.