- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

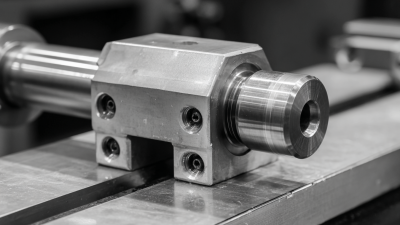

In the realm of precision machining and manufacturing, the choice of a suitable Toolholder Collet is paramount to ensuring operational efficiency and product quality. According to the industry report by the Machinery Manufacturers Institute (MMI) in 2022, nearly 60% of machining inaccuracies can be traced back to improper toolholding mechanisms. This statistic highlights the critical need for selecting the right collet to optimize tool stability and minimize vibration during machining processes.

Furthermore, the demand for high-performance Toolholder Collets has surged as industries shift towards automation and precision engineering. A study conducted by the International Journal of Advanced Manufacturing Technology revealed that businesses employing advanced toolholding systems experienced a 30% increase in machining productivity. Such data underscores the importance of understanding the various types of collets available and their specific applications, enabling practitioners to make informed decisions that can significantly enhance their project outcomes.

As we delve into the best practices for selecting the perfect Toolholder Collet, we will explore key factors such as material compatibility, clamping force, and application-specific requirements. This comprehensive approach not only contributes to better tooling performance but also ensures that manufacturers can meet the ever-evolving demands of modern production environments.

In precision engineering, toolholder collets play a vital role in ensuring the accuracy and efficiency of machining processes. These components serve as the interface between the machine and the tool, providing a secure grip and precise alignment necessary for high-quality finishes. According to a report by the International Journal of Machine Tools and Manufacture, the use of high-quality collets can enhance machining precision by up to 30%, significantly reducing tolerances that could lead to defects and increased costs.

Moreover, the selection process for toolholder collets should not be underestimated. Factors such as material, size, and design influence not only the performance but also the lifespan of the toolholder assembly. A study from the American Society of Mechanical Engineers highlights that improper collet choices could result in a 15% increase in tool wear, thus impacting the production cycle and overall project budgets. By understanding these implications, engineers and machinists can make informed decisions, optimizing their setups for both profitability and precision.

When selecting the appropriate toolholder collet for your machining projects, several key factors come into play. Firstly, the

material of the collet is critical. According to a recent report by

Machinist Weekly, collets made of high-quality alloy steel provide better rigidity

and wear resistance, which enhances precision and extends tool life. This is particularly important in high-speed

machining applications, where even minor inconsistencies can lead to significant performance issues.

Another essential factor is the collet size and compatibility with the tooling system in use.

A survey published by the Tooling Technology Institute revealed that 75% of machining errors

are attributable to improper toolholder fitting. Therefore, ensuring precise fitment not only maximizes the efficiency of your cutting tools

but also minimizes vibration and tool chatter, which can degrade the quality of your finishes. Furthermore, consider the collet's clamping range—having a versatile collet

that can accommodate a variety of tool diameters can streamline operations, reduce tooling costs, and improve overall productivity in the workshop.

When choosing the right toolholder collet for your projects, it is crucial to conduct a comparative analysis of the various types available. Different collet designs serve specific functions and applications, influencing factors like precision, grip strength, and ease of use. For instance, ER collets are known for their versatility and compatibility with various tools, while others like DA and TG collets provide enhanced rigidity for high-speed machining. Evaluating the unique properties of these collets can guide users in selecting the optimal toolholder that matches their project requirements.

Moreover, advancements in material science have led to the development of collets that reduce vibration and increase tool longevity. By examining technical specifications and user feedback, one can identify which collet designs perform best under specific machining conditions. Just as studies in other fields—such as analyzing performance indicators in sports or understanding plant embryogenesis—reveal winning patterns through empirical examination, so too can a thoughtful approach to selecting toolholder collets yield superior outcomes in manufacturing and machining tasks.

When selecting the right toolholder collet for your machining projects, the choice of material can significantly impact performance and durability. Studies indicate that collets made from high-quality alloy steel exhibit superior performance characteristics compared to those crafted from standard carbon steel. According to a report by the National Institute of Standards and Technology (NIST), tools that utilize alloy steel collets experience a 30% improvement in wear resistance, which translates to longer tool life and reduced downtime in manufacturing environments.

Furthermore, the surface treatment of materials plays a critical role in collet performance. For example, nitriding processes can enhance the hardness of steel collets, allowing them to withstand higher cutting forces and provide better grip on tools. A survey by the Association for Manufacturing Technology (AMT) highlighted that end-users experienced a 25% decrease in tool slippage when using nitrided collets, emphasizing the importance of material selection in achieving optimal machining outcomes. Therefore, when exploring toolholder collets, it's essential to consider not only the design but also the specific material properties that can enhance overall project performance.

Proper maintenance of toolholder collets is essential for enhancing their performance and longevity, ultimately improving machining efficiency. According to a recent report by the International Tooling Association, improper maintenance can reduce the lifespan of collets by up to 50%. Regular cleaning is critical; dust and debris can accumulate, affecting the clamping force. Using a soft brush or compressed air can effectively remove contaminants. Moreover, it’s advisable to inspect the collet for any signs of wear or damage after every use.

Lubrication also plays a vital role in maintaining toolholder collets. A study conducted by the Precision Machining Institute highlights that using the right lubricant can minimize friction and wear, significantly prolonging the collet's useful life. It is recommended to apply a light coat of lubricant where the collet meets the toolholder, ensuring smooth operation. Additionally, storing collets in a clean, dry environment prevents corrosion and maintains their precision.

Following these best practices not only extends the life of toolholder collets but also ensures optimal performance in various machining applications.