- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

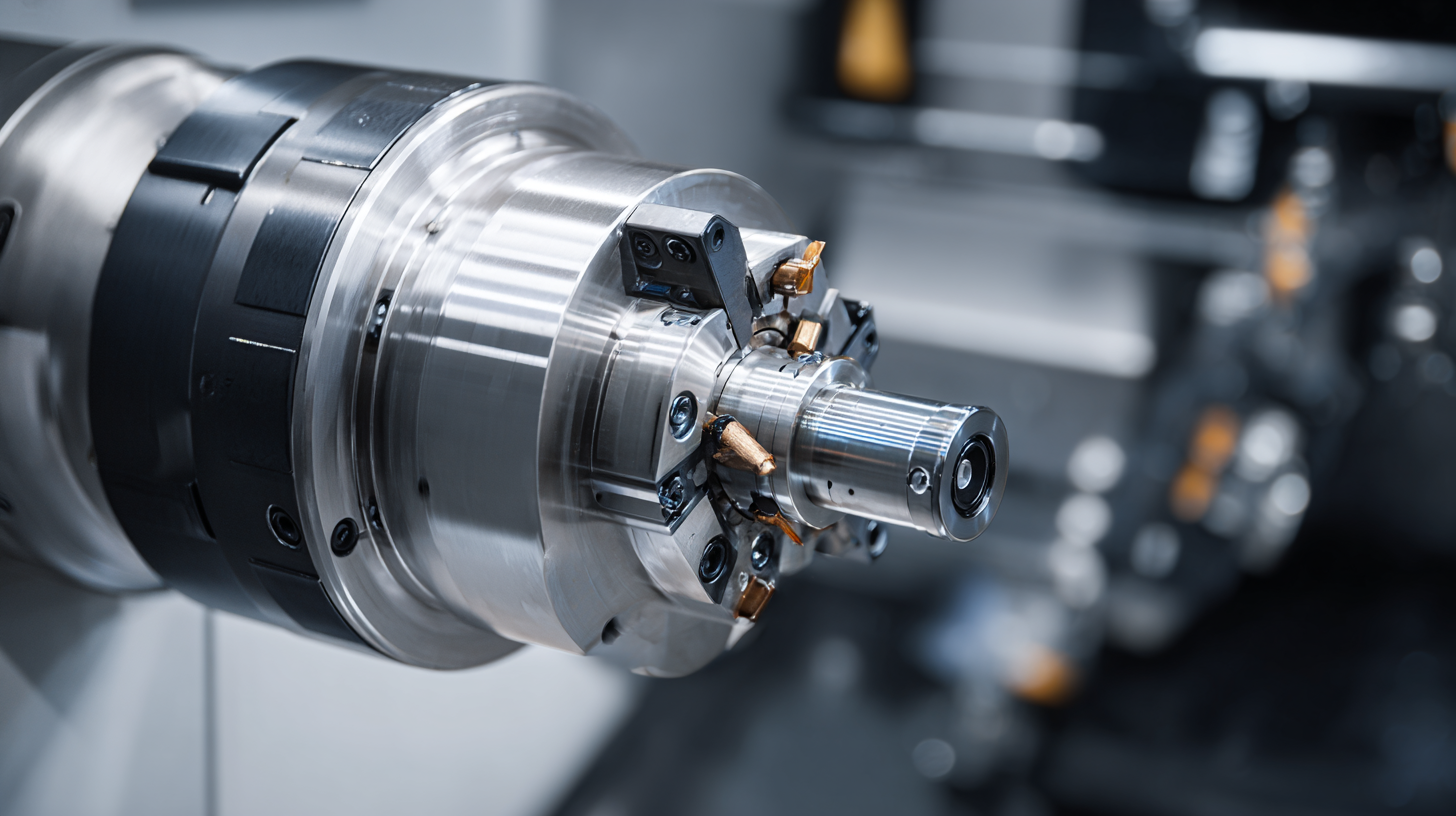

In the rapidly evolving landscape of manufacturing, the demand for precision and efficiency has driven innovation in tooling solutions, particularly for CNC machines. Among these, the CNC lathe collet plays a crucial role in facilitating superior workpiece clamping and accuracy. Recent industry reports indicate that the global market for CNC lathe collets is projected to reach $500 million by 2026, reflecting a compounded annual growth rate (CAGR) of 5.4%.

However, as manufacturers seek to optimize their operations, the exploration of alternative options for CNC lathe collets has gained momentum. These alternatives not only promise cost-effectiveness but also enhance flexibility and adaptability in diverse machining applications. As we delve into innovative alternatives, it's essential to assess their compatibility with existing systems and their potential impact on productivity.

As the manufacturing landscape continuously evolves, innovative collet designs are significantly transforming CNC lathe operations. Recent industry reports indicate that the global CNC lathe market is projected to reach $5.54 billion by 2026, growing at a CAGR of 6.5%. This growth is largely fueled by advancements in collet technology, which enhances precision and efficiency in machining processes. Modern collet systems, such as hydromechanical and quick-change designs, are being adopted to minimize downtime and improve productivity.

Furthermore, the integration of advanced materials, including high-performance composites and heat-resistant alloys in collet production, not only increases durability but also enhances performance under extreme machining conditions.

According to a 2022 market analysis, more than 30% of manufacturers are now prioritizing innovative collet solutions to achieve superior gripping capabilities, critical for high-speed lathe operations. These advancements are positioning manufacturers to better meet the rising demands of precision engineering, especially in industries like aerospace and automotive, where tolerances are stringent.

As these innovative designs proliferate in global markets, the future of CNC lathe operations looks increasingly efficient and reliable.

As the demand for CNC lathe collets increases, so does the exploration of innovative materials that can enhance performance and sustainability. Among these emerging materials, engineered mycelium composites have garnered attention for their unique properties, combining strength with lightweight characteristics. Mycelium, the root structure of fungi, can be processed into a composite material that is not only cost-effective but also environmentally friendly. This characteristic makes it an exciting alternative for traditional CNC collet designs that often rely on more conventional materials.

When considering alternatives for CNC collets, it is crucial to prioritize sustainability without compromising performance. One tip is to explore partnerships with suppliers focused on innovative material solutions, such as mycelium composites, to integrate these sustainable options into your operations. Utilizing materials like these can contribute to a more eco-conscious manufacturing process while maintaining high precision and durability.

Moreover, staying updated on research and developments in mycelium technology can provide insights into enhancing CNC collet design. Engaging with academic and industrial communities will offer opportunities to understand the latest advancements and potential applications. By embracing these innovative materials, businesses can position themselves at the forefront of both sustainability and cutting-edge technology in the global market.

The CNC collet manufacturing sector is currently witnessing significant changes driven by global market dynamics. As manufacturers strive to enhance productivity and precision, innovations in collet design and materials are emerging to meet these demands. Advanced CNC lathes are being equipped with high-performance collets that not only improve clamping force but also reduce vibration during operation. This evolution is essential for industries focused on high-speed machining and intricate component production, as it ultimately impacts the quality and accuracy of finished products.

Supply chain dynamics are also playing a crucial role in the availability and distribution of CNC collets. With globalization, manufacturers are exploring diverse sourcing options to mitigate risks related to single-market dependencies. The rise of digitalization in supply chain management allows companies to track and optimize resources more effectively, ensuring a steady flow of high-quality collets across various regions. Additionally, as sustainability becomes a key focus, manufacturers are increasingly considering eco-friendly materials and production practices, ensuring that their offerings not only meet technical specifications but also align with global environmental standards. These trends point toward a collaborative future where innovation and efficiency harmonize in the CNC collet market.

The evolution of collet design in precision engineering plays a pivotal role in enhancing manufacturing processes, especially in rapidly evolving sectors like cannabis production. As automation increasingly infiltrates various manufacturing arenas, the importance of precision-engineered components, such as CNC lathe collets, cannot be overstated. According to a recent report by a leading industry analyst, the global market for precision engineering components is projected to reach $300 billion by 2026, reflecting a compound annual growth rate (CAGR) of approximately 6.5%. This growth is largely driven by the adoption of advanced technologies, which demand high precision in component design.

In the realm of cannabis manufacturing, for instance, automating processes like pre-roll infusion is becoming vital for efficiency and product quality. Integrating robotics and advanced machinery can lead to cleaner and more consistent manufacturing outputs. The precision required in the manufacturing of such systems enhances not only the product quality but also optimizes operational efficiency. As consumers increasingly demand refined and reliable products, innovative collet designs that accommodate advanced manufacturing machinery become essential for staying competitive in global markets, ensuring that manufacturers align with the highest standards of precision engineering.

The landscape of CNC lathe collet technology is rapidly shifting, fueled by advancements in automation and precision engineering. As the global machine tools market was valued at approximately USD 134.96 billion in 2023, it is projected to reach USD 169.47 billion by 2033, reflecting a robust growth trajectory. This increase emphasizes the necessity for innovative collet alternatives that can enhance the efficiency and productivity of CNC operations across diverse manufacturing settings.

As manufacturing processes become increasingly automated, CNC lathes are set to play a pivotal role in the evolution of machining. For instance, the CNC machines market is expected to burgeon, reaching an astounding $4009.59 million by 2030, highlighting the demand for high-quality, efficient collet systems. The rise of artificial intelligence and smart technologies is also reshaping the machine tools market, making it essential for manufacturers to adapt to these trends by exploring new collet designs that offer better precision and reliability.

**Tip 1:** Consider investing in collets that offer quick-change functionalities to minimize downtime during production runs.

**Tip 2:** Regularly evaluate the compatibility of new collet designs with existing CNC systems to ensure seamless integration and maximize output efficiency.

| Alternative Type | Material | Application Area | Market Region | Trends |

|---|---|---|---|---|

| Hydraulic Collets | Steel | Precision Machining | North America | Increased Precision |

| Capto Collets | Aluminum | Tool Holding | Europe | Modular Tooling |

| Drop-In Collets | Polymer | Lightweight Applications | Asia-Pacific | Cost Efficiency |

| Quick-Change Collets | Titanium | Rapid Production | Latin America | Efficiency in Setup |

| 3D Printed Collets | PLA | Customization | Global | Innovative Fabrication |