- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

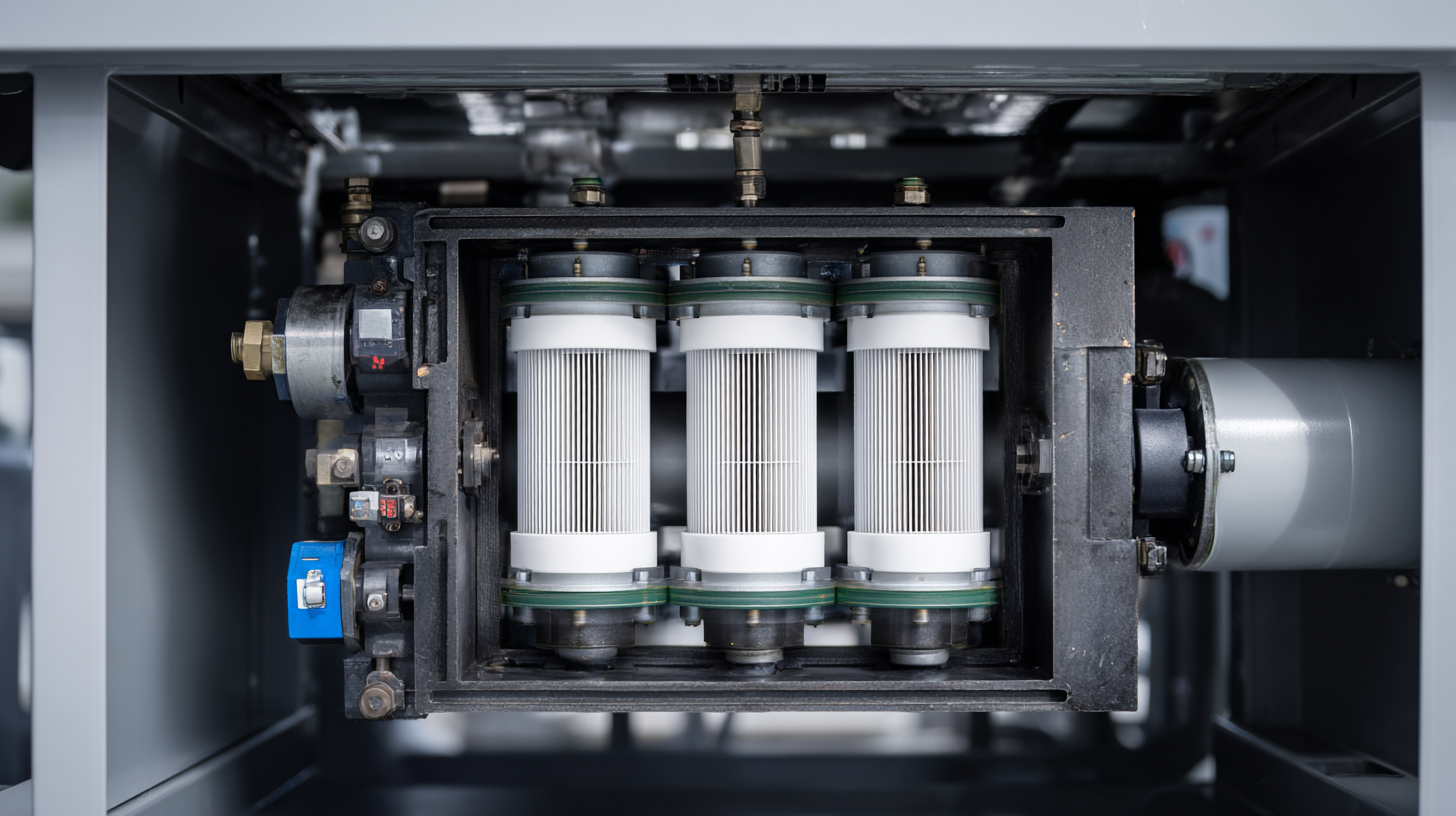

In today's industrial landscape, maintaining optimal efficiency in systems that utilize an Air Water Separator Filter is crucial for achieving peak performance and longevity. These filters play a vital role in removing moisture and contaminants from compressed air systems, ensuring clean and dry air flows throughout the operation. However, many users overlook key strategies to enhance the performance of their Air Water Separator Filter, leading to potential inefficiencies and increased operational costs. In this ultimate guide, we will explore proven tips and best practices to optimize your Air Water Separator Filter's performance, helping you to maximize efficiency, improve reliability, and extend the lifespan of your equipment. Join us as we delve into the essential techniques and insights that can transform your air treatment processes, ensuring your systems operate at their very best.

When it comes to optimizing the performance of air water separator filters, identifying common issues is crucial. According to a recent report by the International Water Association, improper maintenance and outdated technology account for up to 35% of efficiency losses in air water separation systems. One of the primary issues is the accumulation of sludge and particulate matter, which can significantly impair filter functionality. Regular monitoring and maintenance can mitigate these challenges, ensuring that the filters operate at their peak.

Furthermore, filter design plays a vital role in overall efficiency. Research published by the American Society of Mechanical Engineers indicates that air water separators with advanced materials and innovative designs can improve separation efficiency by as much as 25%. Flaws in design can lead to turbulence and reduced flow rates, resulting in increased operating costs and decreased performance. By focusing on upgrading both the technology and the maintenance practices, facilities can enhance their air water separator filters and achieve optimal efficiency.

Regular maintenance of air water separators is crucial for ensuring their optimal performance and efficiency. These systems play a vital role in minimizing water wastage and improving water conservation efforts. To keep your air water separator filters functioning effectively, it is essential to implement a routine maintenance schedule. Regular inspections can help identify potential issues before they escalate, such as build-up of contaminants that can hinder performance. Cleaning the filters and checking seals and connections can prevent leaks and ensure that the system operates smoothly.

In addition to routine inspections, consider integrating advanced materials and technologies that promote greater efficiency in oil/water separation. Recent innovations in hybrid nano-interfacial engineering have shown promise in enhancing the capabilities of separators. By adopting these advanced engineering strategies, not only can you improve the filter’s functionality, but also contribute to broader environmental initiatives, such as reducing overall water consumption and minimizing waste. Staying informed about the latest advancements can aid in the effective management of your air water separator systems, ultimately leading to better resource conservation at home and in the community.

To enhance the performance of air water separator filters, upgrading components is crucial for achieving optimal efficiency. Recent trends in the vacuum pump filtration industry indicate a significant shift towards more eco-friendly and efficient technologies. According to a report, industries relying on vacuum pump equipment are projected to grow as innovations in energy sources and battery technology advance. By modernizing filter elements, manufacturers can significantly improve separation capabilities, which results not only in enhanced performance but also in reduced operational costs.

The integration of advanced materials, such as high-efficiency ceramic substrates, can play a pivotal role in this upgrade process. Research shows that the implementation of honeycomb ceramic carriers in exhaust treatment systems can boost filtering efficiency significantly. Additionally, coupling programmable devices with established technologies, like adjustable voltage regulators, is another step forward. This ensures that systems maintain optimal performance under varying operational conditions, enhancing overall productivity and sustainability in the long run. By focusing on these upgrades, industries can better adapt to the increasing demands for efficiency and environmental responsibility.

Proper installation and system integration of air water separator filters are crucial for maximizing their performance and ensuring optimal efficiency. First and foremost, it is essential to select the right installation location, ideally positioning the filter where it can effectively capture contaminants and moisture from the compressed air system. Avoiding areas with excessive vibration or temperature fluctuations will help maintain the filter’s integrity and efficiency. Additionally, ensuring that all connection points are airtight will prevent leaks, which can compromise the system's overall performance.

Monitoring the performance of your air water separator filter is crucial for maintaining optimal efficiency and prolonging its lifespan. To measure the effectiveness of your filter, start by assessing key performance metrics such as pressure drop, flow rate, and contaminant removal efficiency. Regularly analyzing these metrics will enable you to identify any deterioration in filter performance, allowing for timely maintenance or replacement. Utilizing digital monitoring tools can simplify this process, providing real-time data that aids in making informed decisions about filter management.

In addition to tracking performance metrics, it is essential to analyze the data collected to understand trends and variances over time. This analysis can reveal underlying issues such as clogging or improper installation, which might not be evident through casual observation. Implementing a systematic review of filter performance can help in predicting when maintenance is due, thus avoiding unexpected downtimes and ensuring your air water separator operates at peak efficiency. Establishing a routine for performance analysis not only safeguards the system’s integrity but also optimizes operational costs through proactive measures.