- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right Universal Milling Head is a critical decision for anyone involved in precision machining and manufacturing processes. This sophisticated tool is fundamental for achieving accuracy and efficiency in milling operations, making it essential for both hobbyists and professionals alike. With a myriad of options available on the market, selecting the right Universal Milling Head can be overwhelming. The wrong choice can lead to subpar performance, increased costs, and wasted time.

To help you navigate this crucial selection process, we have compiled ten essential tips that will guide you in evaluating various Universal Milling Heads. From understanding the specifications and key features to assessing compatibility with your existing machinery, these tips will empower you to make an informed decision. Whether you are looking to upgrade your workshop or invest in a new Universal Milling Head, the considerations outlined in this guide will provide valuable insights to ensure you select the perfect tool for your milling needs.

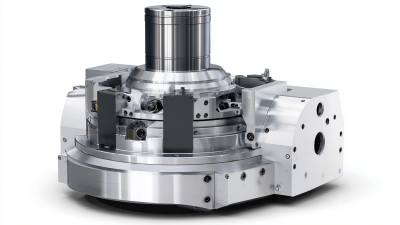

A universal milling head is a vital component in many machining operations, providing versatility and precision. It is designed to perform a variety of milling tasks, enabling users to execute complex shapes and contours. Understanding its purpose is crucial for selecting the right model that meets specific production needs. Unlike standard milling heads, a universal milling head allows for adjustments in angular position, giving operators the ability to work on different surfaces and geometries efficiently.

The main advantage of a universal milling head lies in its adaptability. It can be tilted, rotated, and swiveled, allowing for angled cutting which is particularly beneficial for producing multi-faceted components. This versatility not only enhances productivity but also broadens the potential applications in manufacturing processes. Knowing how to leverage the capabilities of a universal milling head can lead to increased precision and reduced machining times, ultimately contributing to higher quality output and improved operational efficiency.

When selecting a universal milling head, it's crucial to focus on key features that significantly impact performance and efficiency. One essential feature is the spindle speed range; according to a recent report by Grand View Research, improved spindle speed capabilities can increase productivity in machining operations by up to 30%. This enhancement allows for versatile machining of various materials, making it a vital consideration for professionals looking to maximize their milling efficiency.

Another important aspect to consider is the construction quality and rigidity of the milling head. A study published in the Journal of Manufacturing Science and Engineering emphasizes that higher rigidity in milling heads can reduce vibrations, resulting in better surface finish and dimensional accuracy. As these factors can lead to substantial savings in time and costs for manufacturers, opting for heads made from high-grade materials such as hardened steel or cast iron becomes essential. Additionally, features like ease of angle adjustment and tool compatibility can further enhance operational versatility, catering to a broad range of milling applications in different industries.

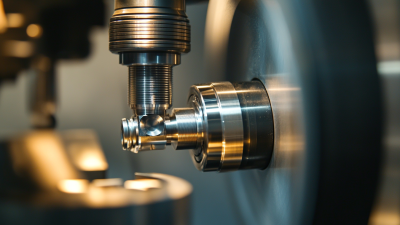

When selecting the right universal milling head, evaluating compatibility with your milling machine is crucial. This step ensures that the chosen head matches the specifications and operational requirements of your existing setup, thus maximizing efficiency. According to industry reports, mismatched components can lead to significant inefficiencies, often estimated at a 15-20% reduction in processing speed due to improper fit and increased wear. Understanding the dimensions, connection types, and operational limits of your milling machine will guide you in finding the optimal universal milling head.

In modern manufacturing processes, tool wear monitoring has become increasingly essential to maintaining product quality. For instance, studies indicate that real-time monitoring can detect abnormal wear patterns, allowing for timely interventions that improve the lifespan of milling tools. As highlighted in recent studies on tool performance, the integration of technologies such as feedforward neural networks in evaluating operational conditions can enhance decision-making when pairing milling heads. These advancements not only optimize processing time but also contribute to a more sustainable manufacturing environment by reducing waste and rework associated with tool degradation.

When selecting a universal milling head, assessing material and build quality is crucial for ensuring durability and performance. High-quality milling heads are typically constructed from robust materials like chrome-molybdenum steel or high-grade aluminum, which can withstand the rigors of machining environments. According to a report by the American Society of Mechanical Engineers (ASME), tools made from premium materials can enhance lifespan by up to 40% compared to those made from standard alloys. This longevity results not only from resistance to wear and tear but also from greater stability during operation.

In addition to material composition, the design and engineering of the milling head play a significant role in its reliability. Precision manufacturing techniques, such as CNC machining, contribute to tighter tolerances and superior performance. The National Tooling and Machining Association (NTMA) emphasizes that milling heads with precise build quality can lead to a decrease in operational downtime, thus increasing productivity by roughly 15%. Therefore, scrutinizing the build quality alongside the material used can lead to more informed purchasing decisions and ultimately contribute to the efficiency of your milling operations.

When selecting a universal milling head, budget considerations play a pivotal role in ensuring you get the best value for your money. It is crucial to determine how much you are willing to invest while keeping in mind the potential long-term benefits. High-quality milling heads may require a larger upfront cost but often provide superior performance, durability, and efficiency that can lead to significant savings over time. Therefore, allocating a budget that reflects your needs and anticipated usage is essential.

Moreover, comparing features and prices across different models can help you identify the best options within your budget. Look for heads that offer outstanding functionality without compromising on quality. It's advisable to read reviews and obtain recommendations to ensure the chosen head will meet your specific machining requirements. By focusing on value for money, you can balance affordability with quality, ultimately leading to a more satisfying investment in your milling operations.