- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

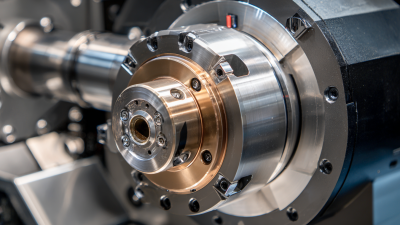

In today's competitive manufacturing landscape, optimizing machining processes is crucial for enhanced productivity and efficiency. The Universal Milling Head has emerged as a pivotal tool, offering versatility and precision in various milling applications. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach $117.72 billion by 2026, driven by the increasing demand for high-precision components across sectors such as aerospace, automotive, and medical devices. Incorporating a Universal Milling Head can significantly improve machining capabilities, enabling manufacturers to reduce cycle times and improve part accuracy. By leveraging best practices and insights related to this essential component, businesses can stay ahead of the curve, ensuring they not only meet but exceed evolving customer expectations while maximizing their operational efficiency.

A universal milling head is a versatile tool that enhances the capabilities of machining processes. Unlike standard milling heads, which may only operate at fixed angles, universal milling heads can tilt and rotate in multiple directions. This feature allows for complex workpieces to be machined with precision, increasing productivity and reducing the need for multiple setups. The flexibility of a universal milling head means that manufacturers can handle a variety of materials and designs, leading to more efficient operations.

**Tips:** When selecting a universal milling head, consider its construction materials and compatibility with existing milling machines. It's also essential to ensure that the head offers easy adjustments for angle and height, allowing for quick repositioning during machining tasks. Regular maintenance is crucial; check for wear and tear on the gears and ensure lubrication is maintained.

Another advantage of the universal milling head is its ability to perform not only milling but also drilling and boring operations. This multi-functionality reduces the number of machines required in a workshop, saving both space and costs. Moreover, with the proper fixtures and attachments, users can exploit the full potential of their machines to execute even the most intricate designs effectively.

**Tips:** Invest in high-quality cutting tools tailored for the specific materials you are working with. Additionally, practice setting up workpieces securely on the milling machine to ensure accuracy and safety during operations.

| Feature | Description | Benefits | Best Practices |

|---|---|---|---|

| Versatility | Able to perform various milling operations. | Increases efficiency and reduces setup time. | Use for different materials to maximize utility. |

| Precision | Designed for high accuracy in cutting operations. | Ensures quality and reduces waste. | Regular calibration and maintenance checks are essential. |

| Adaptability | Can be integrated with various tools and attachments. | Enhances functionality for complex tasks. | Choose the right attachments for your specific projects. |

| Efficiency | Optimized for faster machining speeds without sacrificing quality. | Reduces cycle time, increasing overall production rate. | Implementing effective workflows can enhance performance. |

| Ease of Use | User-friendly controls and settings. | Faster training and reduced operator errors. | Provide comprehensive training and documentation. |

When selecting the right universal milling head for your machining process, several key factors come into play. First and foremost, compatibility with your existing machinery is crucial. Ensure that the milling head can easily integrate with your milling machine's specifications, including spindle size and taper type. Compatibility ensures smooth operation, minimizes wear on the equipment, and enhances overall machining efficiency.

Another important factor to consider is the range of operations the milling head can perform. Look for a universal milling head that offers versatility in terms of angles and positioning. This capability allows for various machining tasks, from simple milling to complex contouring. Additionally, assess the stiffness and rigidity of the milling head, as these qualities contribute to improved precision and reduced vibration during operation, thereby enhancing the quality of the finished product. Opting for a model that incorporates advanced features, such as adjustable feed rates or integrated tooling systems, can further optimize your machining process and yield better results.

Setting up a universal milling head effectively can significantly boost the efficiency of your machining processes. According to a study by the National Institute of Standards and Technology (NIST), proper alignment and setup of milling equipment can improve machining accuracy by up to 20%. To achieve optimal results, ensure that the milling head is leveled correctly before starting any project. This step not only enhances precision but also reduces wear on tooling, leading to longer lifespan and better overall performance.

Setting up a universal milling head effectively can significantly boost the efficiency of your machining processes. According to a study by the National Institute of Standards and Technology (NIST), proper alignment and setup of milling equipment can improve machining accuracy by up to 20%. To achieve optimal results, ensure that the milling head is leveled correctly before starting any project. This step not only enhances precision but also reduces wear on tooling, leading to longer lifespan and better overall performance.

In addition to leveling, selecting the appropriate cutting parameters is crucial. Research from the American Society of Mechanical Engineers (ASME) indicates that using the correct feed rate and spindle speed can lead to productivity increases of up to 30%. Experimenting with different materials and understanding their specific requirements can further enhance operational efficiency. Incorporating real-time monitoring systems can also help machinists adapt to changing conditions swiftly, thereby maximizing output and minimizing downtime. Implementing these best practices will ensure that you fully leverage the capabilities of your universal milling head, driving significant improvements in your machining operations.

In the pursuit of enhancing precision and quality in machining processes, utilizing a universal milling head can offer significant advantages. This versatile tool enables operators to adjust angles and positions easily, accommodating a variety of machining tasks. By allowing for precise control over cutting actions, the universal milling head minimizes errors and reduces variations in product dimensions. Implementing advanced techniques such as dynomometric testing to calibrate the milling head can further optimize accuracy, ensuring that every cut is consistently within tolerance.

Additionally, adopting best practices like regular maintenance and proper tool selection is crucial in maximizing the performance of the milling head. Choosing appropriate cutting tools based on the material being machined and the specific requirements of the job can greatly affect the outcome. Moreover, training personnel on the latest machining technologies and techniques fosters a skilled workforce capable of leveraging the full potential of the universal milling head. This comprehensive approach not only enhances the precision of machining processes but also leads to improved overall quality in the final products.

Using universal milling heads can significantly enhance the versatility of your machining process, but they come with their own set of challenges. One common issue is the misalignment during setup, which can lead to inaccuracies in machining. To overcome this, it's essential to ensure that the head is precisely aligned before starting the operation. Employing dial indicators or laser alignment tools can aid in achieving better accuracy, thus minimizing the risk of errors.

Another challenge lies in maintaining the proper cutting parameters. Operators often face difficulties selecting the optimal feed rate and spindle speed, which can affect the surface finish and tool life. To tackle this, it's advisable to refer to the manufacturer’s recommendations for various materials and workpiece conditions. Regular training and skill enhancement for operators can also contribute to better decision-making, ensuring that the universal milling head is utilized effectively to optimize processing times and quality.