- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the ever-evolving manufacturing landscape, optimizing the Spindle Angle Head has become a crucial factor for enhancing machining performance. As industries aim for increased efficiency and precision in their operations, understanding how to best utilize technological advancements in spindle design is essential. Renowned expert in cutting tool technology, Dr. John Thompson, once stated, "The right adjustment of the Spindle Angle Head can transform machining processes, allowing for greater accuracy and reduced cycle times."

To harness the full potential of the Spindle Angle Head, manufacturers must explore innovative optimization strategies. By focusing on critical parameters such as angle adjustment precision, tool engagement metrics, and cooling efficiency, businesses can significantly improve their machining outcomes. As we delve deeper into the intricacies of Spindle Angle Head configuration, it becomes clear that adeptly leveraging its capabilities can lead to remarkable gains in both productivity and quality.

Furthermore, the integration of advanced monitoring and control systems is paving the way for real-time adjustments and enhanced performance metrics. By adopting a comprehensive approach to Spindle Angle Head optimization, manufacturers not only elevate their machining operations but also set a foundation for future advancements in the industry.

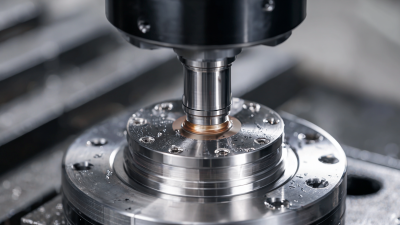

The spindle angle head is a crucial component in modern machining, designed to enhance versatility and efficiency during the cutting process. By allowing the spindle to tilt at various angles, this device enables operators to approach workpieces from multiple orientations. This flexibility is particularly beneficial in complex machining tasks, where achieving precision is essential. The capability to machine at different angles not only reduces the necessity for multiple setups but also improves productivity by minimizing tool changes and repositions.

In addition to enhancing flexibility, the spindle angle head contributes to improved surface finishes and intricate details in machining processes. When integrated effectively, it allows for the use of specialized tooling that can tackle challenging geometries without compromising accuracy. Correctly adjusting the spindle angle can also optimize chip removal and minimize tool wear, leading to longer tool life and reduced production costs. Understanding the function and advantages of spindle angle heads is vital for manufacturers aiming to refine their machining operations and achieve higher quality outcomes.

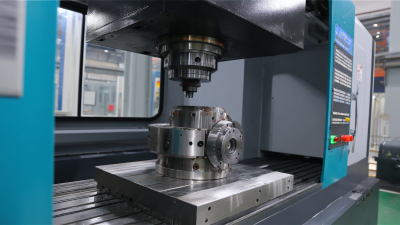

The performance of a spindle angle head is critically influenced by several key factors that determine its effectiveness in enhancing machining operations. One of the most significant factors is the spindle speed capability, which directly affects material removal rates and overall productivity. According to industry research, optimizing spindle speeds within the range of 5,000 to 20,000 RPM can lead to a 30% increase in efficiency when machining materials like aluminum and titanium. This substantial improvement is often attributed to reduced cycle times and enhanced surface finish.

Another crucial factor is the design of the angle head itself, particularly its rigidity and alignment. A well-engineered angle head with high stiffness can minimize vibration during machining, yielding a more stable cutting environment. Data from technical studies suggest that reducing angular deflection by just 0.001 inches can improve tool life by up to 25%, which translates to fewer tool changes and decreased downtime. Additionally, the choice of cooling and lubrication systems within the spindle angle head plays a pivotal role, as effective cooling can prevent excessive heat buildup, further maintaining machining accuracy and extending tool longevity.

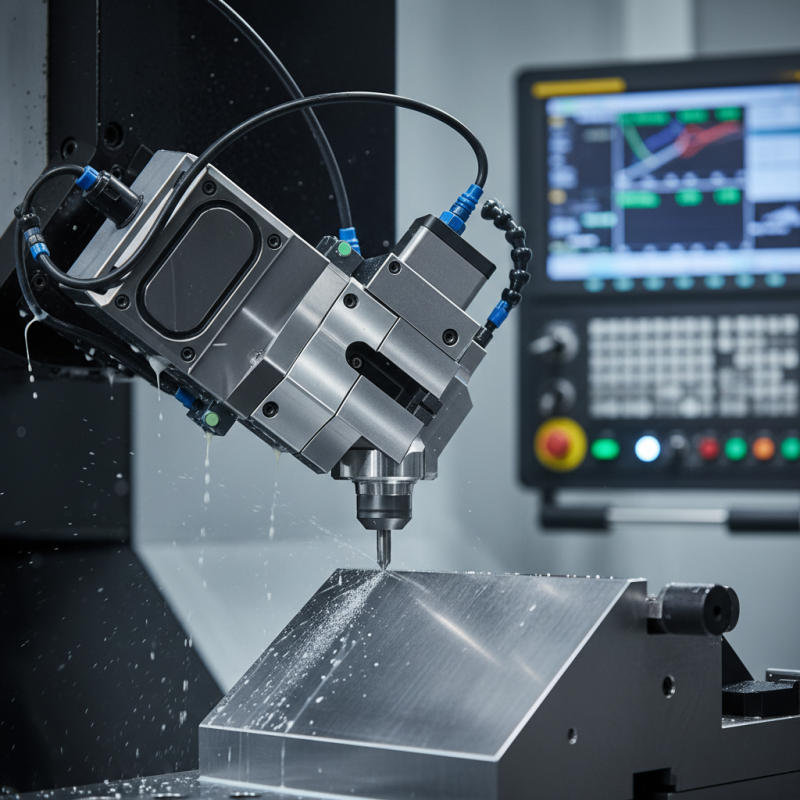

Optimizing spindle angle adjustments is crucial for enhancing machining performance in various manufacturing processes. One effective technique involves using advanced programming strategies that allow for precise control over spindle positioning. By incorporating adaptive machining algorithms, operators can dynamically adjust spindle angles based on real-time feedback from cutting conditions. This approach not only improves the accuracy of machining operations but also significantly reduces tool wear and enhances surface finish quality.

Another technique includes the implementation of precision angle-setting tools, which provide the ability to fine-tune spindle angles with high accuracy. These tools can be used in conjunction with measurement systems that detect the alignment and geometry of the workpiece. By ensuring that the spindle angle matches the optimal cutting trajectory, machinists can achieve more efficient chip removal while maintaining consistency in part quality. Additionally, regular maintenance and calibration of the spindle angle head can prevent deviations and sustain peak performance over time, thereby maximizing the productivity of machining operations.

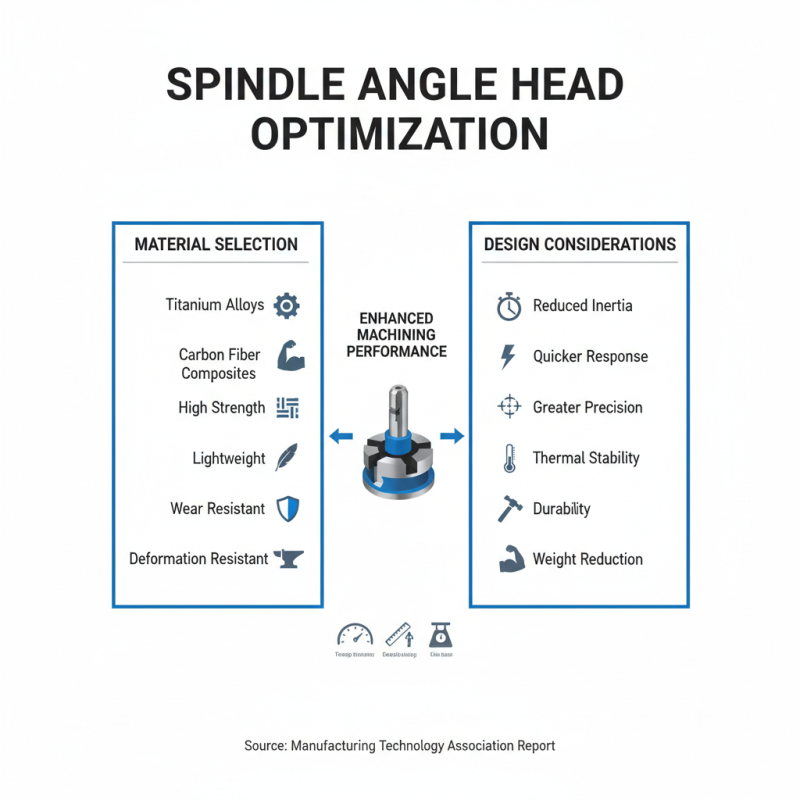

When optimizing a spindle angle head for enhanced machining performance, material selection and design considerations play critical roles. The choice of materials can significantly impact durability, weight, and thermal stability of the spindle angle head. According to a report by the Manufacturing Technology Association, using high-strength, lightweight materials such as titanium alloys and carbon fiber composites can reduce inertia, allowing for quicker response times and greater precision during machining operations. These materials also exhibit superior resistance to wear and deformation, which is essential in maintaining consistent performance under heavy workload conditions.

Moreover, design considerations such as geometry and heat dissipation mechanisms must be addressed to maximize efficiency. The implementation of advanced finite element analysis (FEA) techniques can help in creating an optimized design by predicting stress points and potential failures. Research from the International Journal of Advanced Manufacturing Technology indicates that innovative cooling channels integrated into the spindle design can improve temperature management during high-speed machining, ultimately extending tool life and enhancing machining quality. By focusing on these aspects, manufacturers can significantly improve the performance and reliability of spindle angle heads in various machining applications.

Monitoring and maintenance of spindle angle heads play a critical role in enhancing machining efficiency. Regular monitoring helps identify wear and tear, which can prevent unexpected breakdowns and costly downtime. Utilizing vibration analysis and thermal imaging can provide valuable insights into the operational status of the spindle. By keeping track of these parameters, operators can make informed decisions regarding maintenance schedules and operational adjustments, ensuring that the spindle operates within optimal parameters.

Additionally, implementing a robust maintenance program is essential for sustaining peak performance. This includes routine cleaning, lubrication, and inspection of components to avoid accumulation of debris and ensure smooth functioning. Operators should also be trained to recognize early signs of mechanical issues or misalignment, which can impact machining quality. By fostering a culture of proactive maintenance, organizations can enhance the longevity of their spindle angle heads, reduce repair costs, and ultimately improve overall machining efficiency.