- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

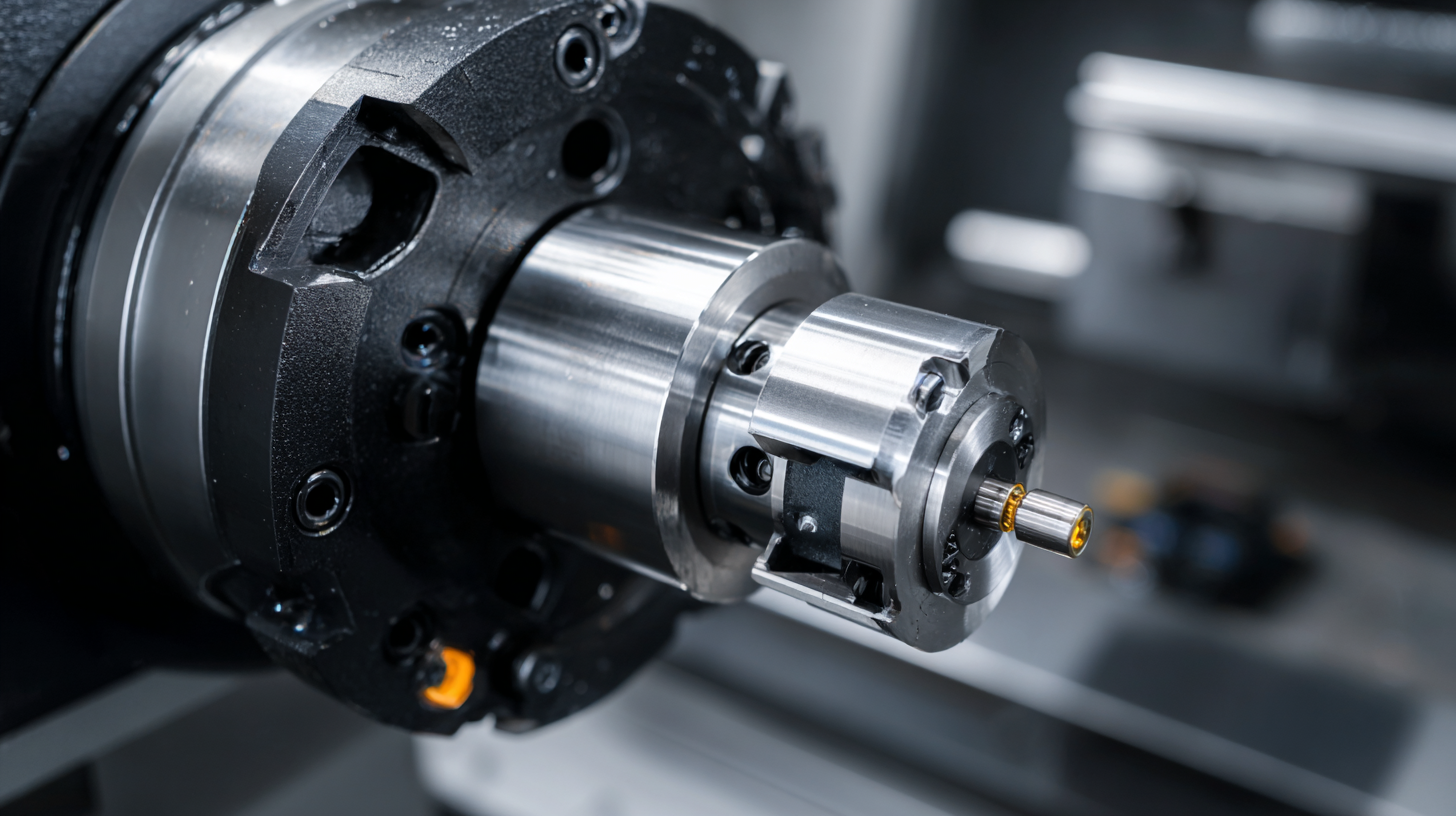

In the world of CNC machining, precision and efficiency are paramount, and one of the key components that significantly enhances these attributes is the Pull Type Collet. This innovative tool holds the capability to securely grip various workpieces while minimizing tool deflection and vibration, which are critical factors in achieving high-quality finishes and accurate dimensions. As the industry evolves, understanding the intricacies of Pull Type Collets becomes essential for machinists looking to maximize their equipment's performance. This guide will delve into the various types and applications of Pull Type Collets, illustrating how their unique design and functionality contribute not only to enhanced machining results but also to improved operational workflows. By exploring the benefits and proper usage of Pull Type Collets, manufacturers can unlock new levels of precision and productivity in their CNC machining processes.

Pull type collets have emerged as a critical component in enhancing CNC machining performance due to their unique design advantages. These collets provide a more secure grip on tools, which is essential for maintaining precision during high-speed operations. According to industry reports, utilizing pull type collets can improve machining accuracy by up to 20%, as they minimize tool deflection and chatter. This precision is particularly valuable in complex machining tasks where even minor deviations can lead to significant quality issues.

However, many shops still encounter common pitfalls when working with collets, particularly ER collets. Factors such as improper assembly and inadequate maintenance can lead to premature wear and reduced performance. It is reported that up to 30% of machining errors can be attributed to issues related to tool holding. Ensuring that collets are inspected regularly and properly maintained can mitigate these errors. Emphasizing education on collet design benefits and best practices not only enhances efficiency but also extends tool life, ultimately driving down operational costs and improving overall productivity.

Pull type collets offer significant advantages over traditional collet types in CNC machining, primarily due to their design and functionality. Unlike conventional collets that expand upon tightening, pull type collets maintain a consistent gripping force through a more integral engagement method. This results in improved precision and stability during machining operations, ultimately enhancing the overall performance of CNC machinery.

Pull type collets offer significant advantages over traditional collet types in CNC machining, primarily due to their design and functionality. Unlike conventional collets that expand upon tightening, pull type collets maintain a consistent gripping force through a more integral engagement method. This results in improved precision and stability during machining operations, ultimately enhancing the overall performance of CNC machinery.

Furthermore, the ease of use associated with pull type collets can lead to reduced setup times and higher efficiency. Their design minimizes tool change complexity, allowing operators to quickly switch out tools without compromising on rigidity or accuracy. As a result, manufacturers can achieve tighter tolerances and better surface finishes, addressing the increasing demands for high-quality output in competitive markets. Thus, the transition from traditional collet types to pull type collets represents a significant step forward in refining CNC machining processes.

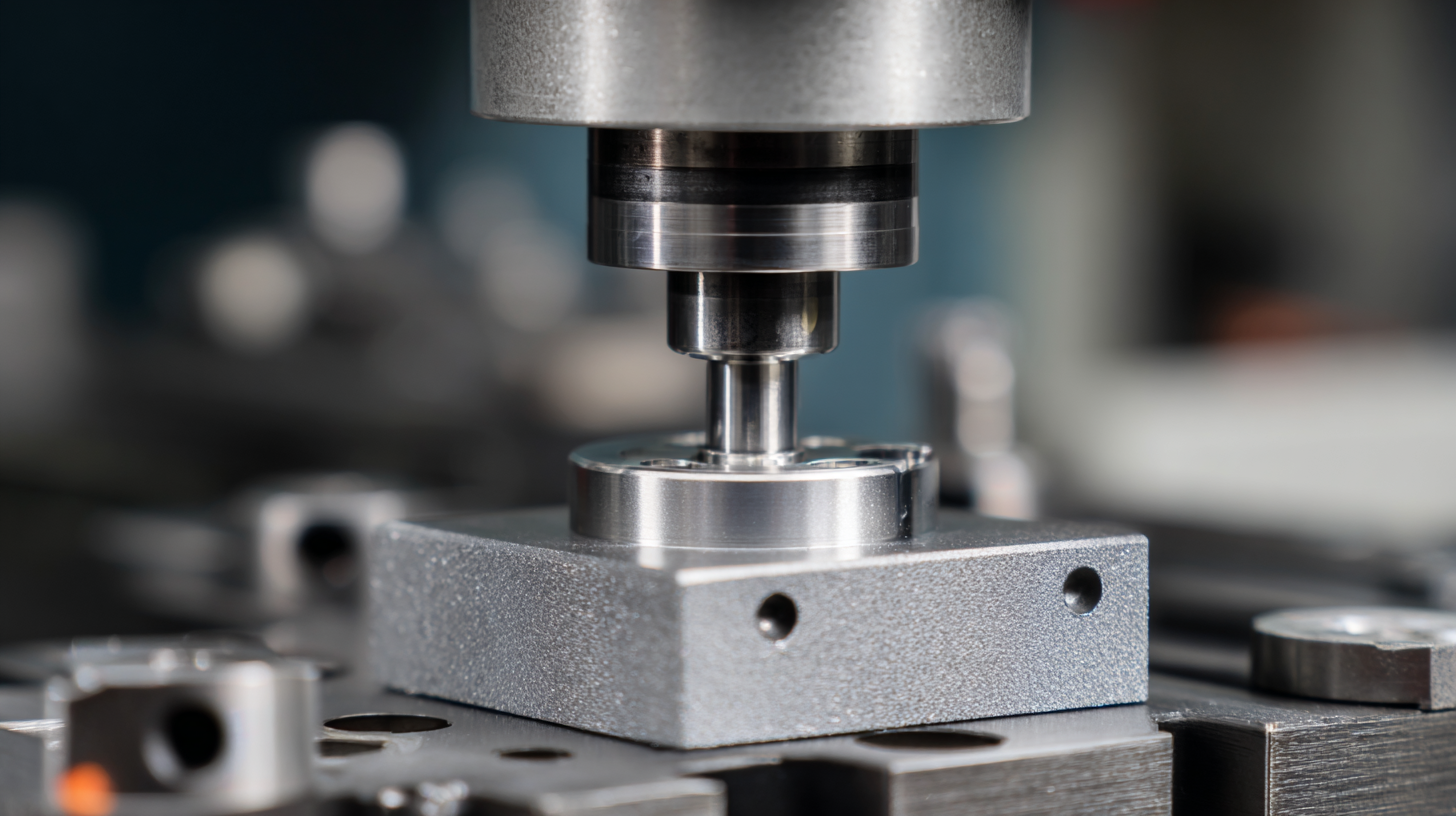

The efficiency of CNC machining heavily relies on the components used in the process, and pull type collets stand out as a game-changer in enhancing this efficiency. Unlike traditional collets, pull type collets are designed to maximize gripping force and minimize runout, ensuring that tools remain stable during high-speed operations. This stability translates to improved accuracy in machining, reducing the likelihood of errors and rework. In high-precision applications, even the slightest variance can lead to significant discrepancies, thus showcasing how the use of pull type collets can bolster overall machining precision.

Furthermore, the ease of installation and versatility of pull type collets contribute substantially to CNC machining efficiency. These collets can accommodate a wide range of tool sizes and types, allowing operators to quickly change tools without extensive downtime. This adaptability not only enhances workflow but also enables manufacturers to respond swiftly to changing production demands. By integrating pull type collets into the CNC machining process, companies can achieve higher throughput, enhance product quality, and ultimately improve their bottom line, solidifying the importance of these tools in modern manufacturing environments.

This chart compares the efficiency of pull type collets and traditional collets in CNC machining, measuring parameters such as gripping force, tool life, and machining accuracy based on industry data.

Maintaining pull type collets is essential for achieving optimal performance in CNC machining. Regular inspection is crucial; users should check for any signs of wear or damage, such as cracks or chips. Keeping the collets clean from shavings and debris helps prevent misalignment and ensures a secure grip on tools. A simple cleaning with an appropriate solvent and a soft brush can prolong the life of the collet and enhance machining accuracy.

Lubrication is another essential aspect of maintenance. Using a suitable lubricant specifically designed for collets can reduce friction and wear during operation. Applying the lubricant sparingly to the collet's taper and threads allows for smooth operation without causing contamination to the workpiece. Additionally, after prolonged use, it is advisable to periodically recalibrate the collet to maintain its precision and performance.

Taking these maintenance steps not only extends the lifespan of pull type collets but also significantly contributes to the overall efficiency and accuracy of CNC machining processes.

In the realm of CNC machining, pull type collets have become indispensable across various industries due to their ability to enhance precision and efficiency. These collets offer a secure grip on tools, allowing for consistent and accurate machining, which is crucial in sectors ranging from aerospace to automotive manufacturing. For instance, in aerospace, where tolerances are minimal and performance is critical, the reliable clamping of pull type collets ensures that components are machined to the highest standards, reducing the likelihood of errors and rework.

Tip: To maximize the benefits of pull type collets, regularly inspect them for wear and ensure they are cleaned properly after use. This maintenance not only extends their lifespan but also keeps machining accurate and effective.

In the medical device industry, the high precision required for manufacturing critical components further emphasizes the role of pull type collets. Their ability to maintain tight tolerances is essential when working with delicate materials and complex geometries. By utilizing these collets, manufacturers can enhance the performance of their CNC machines, producing top-quality products while adhering to strict regulatory standards.

Tip: Consider using collet systems that are specifically designed for the materials you are working with. Different materials may require different collet designs to achieve optimal results.

| Industry | Application | Benefits of Pull Type Collets | Material Compatibility |

|---|---|---|---|

| Automotive | Parts Manufacturing | Increased Clamping Force | Steel, Aluminum |

| Aerospace | Component Fabrication | Enhanced Precision | Titanium, Composite Materials |

| Medical Devices | Surgical Instruments | Improved Tolerance | Stainless Steel, Plastics |

| Electronics | Circuit Board Manufacturing | Consistent Accuracy | Copper, Silicon |

| Energy | Turbine Manufacturing | Higher Load Capacity | Nickel Alloys, Composites |