- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

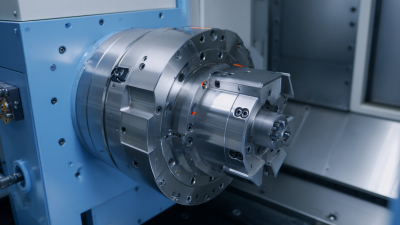

In the realm of precision machining, selecting the right Tapping Machine Collets is crucial for achieving optimal efficiency and productivity. According to a report by Market Research Future, the global market for machine tools is projected to experience a CAGR of 6.5% from 2021 to 2027, which emphasizes the increasing demand for high-quality machining solutions. Properly chosen collets not only improve the accuracy of tapping operations but also enhance tool life, resulting in significant cost savings for manufacturers. A survey conducted by the International Society for Precision Engineering and Nanotechnology highlights that 72% of manufacturers report improved machining efficiency when utilizing high-quality collets suited for their specific applications. This underscores the importance of understanding the various types of Tapping Machine Collets and their corresponding features to ensure that machining processes are not only efficient but also meet the stringent quality demands of modern manufacturing.

Selecting the right tapping machine collets is crucial for achieving optimal machining efficiency, and understanding the different types available is the first step in this process. Collets come in several forms, each designed to handle specific applications and materials. For instance, standard collets are widely used for general tapping tasks, providing reliable holding power for a range of tap sizes. These are ideal for most production environments where versatility is key.

However, specialized collets, such as those designed for high-speed tapping, offer unique advantages. High-speed collets are engineered to minimize vibration and improve accuracy, making them suitable for intricate operations requiring precision. Furthermore, there are also collets designed for specific thread types or sizes, ensuring consistent and dependable results in specialized applications. By understanding the distinct characteristics and benefits of each type of collet, machinists can select the most appropriate option for their specific machining needs, ultimately enhancing efficiency and product quality.

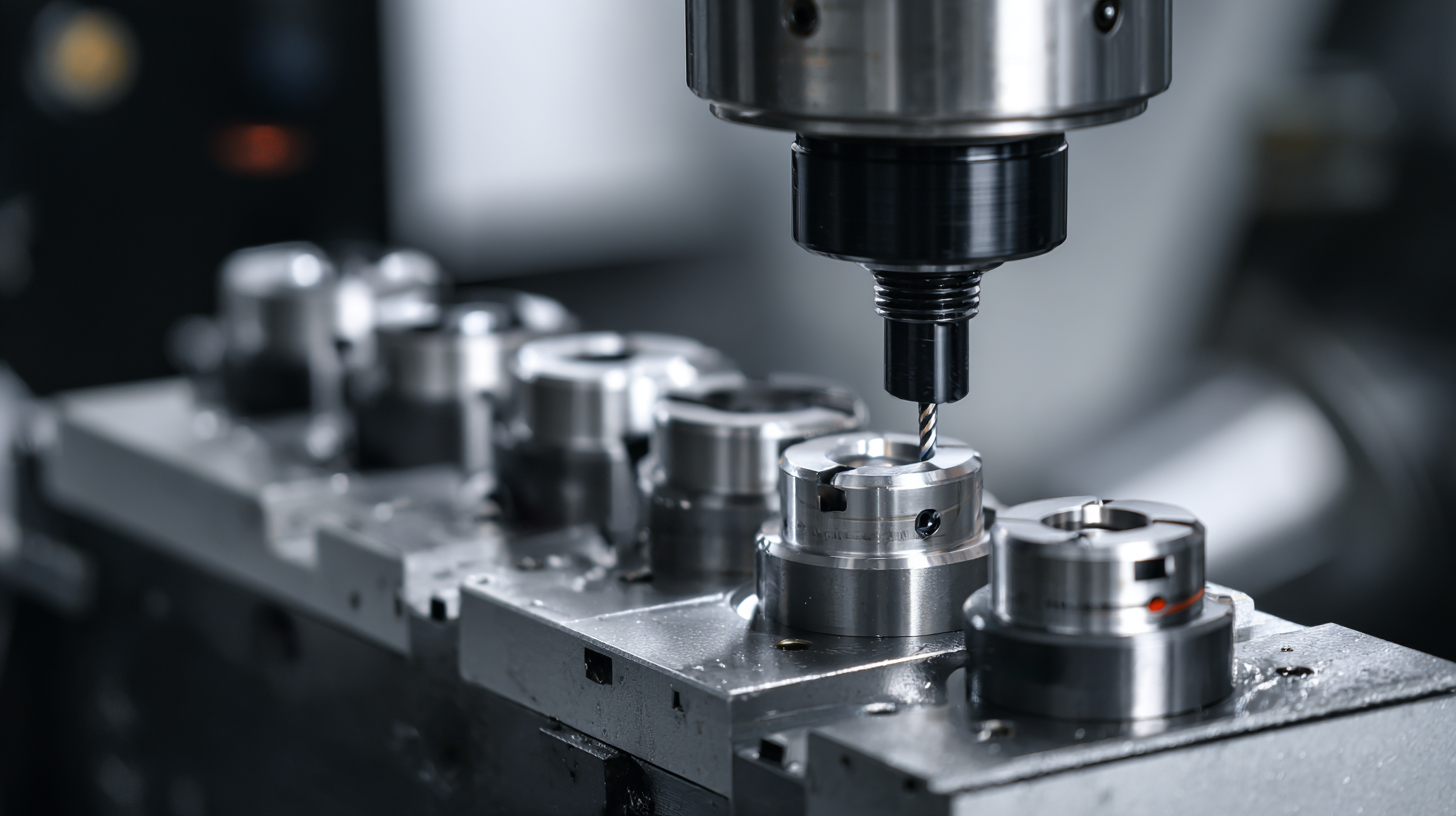

When selecting tapping machine collets, several key factors must be considered to ensure optimal machining efficiency. Firstly, the size and type of the tap are crucial; collets should match the shank size of the taps being used. This precision ensures a secure grip, minimizing tool slippage that can lead to inconsistent thread quality or damage to the workpiece. Additionally, factors such as the material of the collet should be evaluated, as different materials offer varying levels of durability and performance under high speed or heavy-duty applications.

Another essential aspect to consider is the collet's design and compatibility with the tapping machine. Some machines may require specific collet shapes, such as standard hex or round types, which directly impacts the ease of tool change and overall machining workflow. Furthermore, the clamping force exerted by the collet should be appropriate for the machining operation at hand; too much force can deform delicate taps, while too little can cause them to loosen during use. By carefully evaluating these factors, operators can select collets that not only enhance machining efficiency but also extend the lifespan of both taps and machinery.

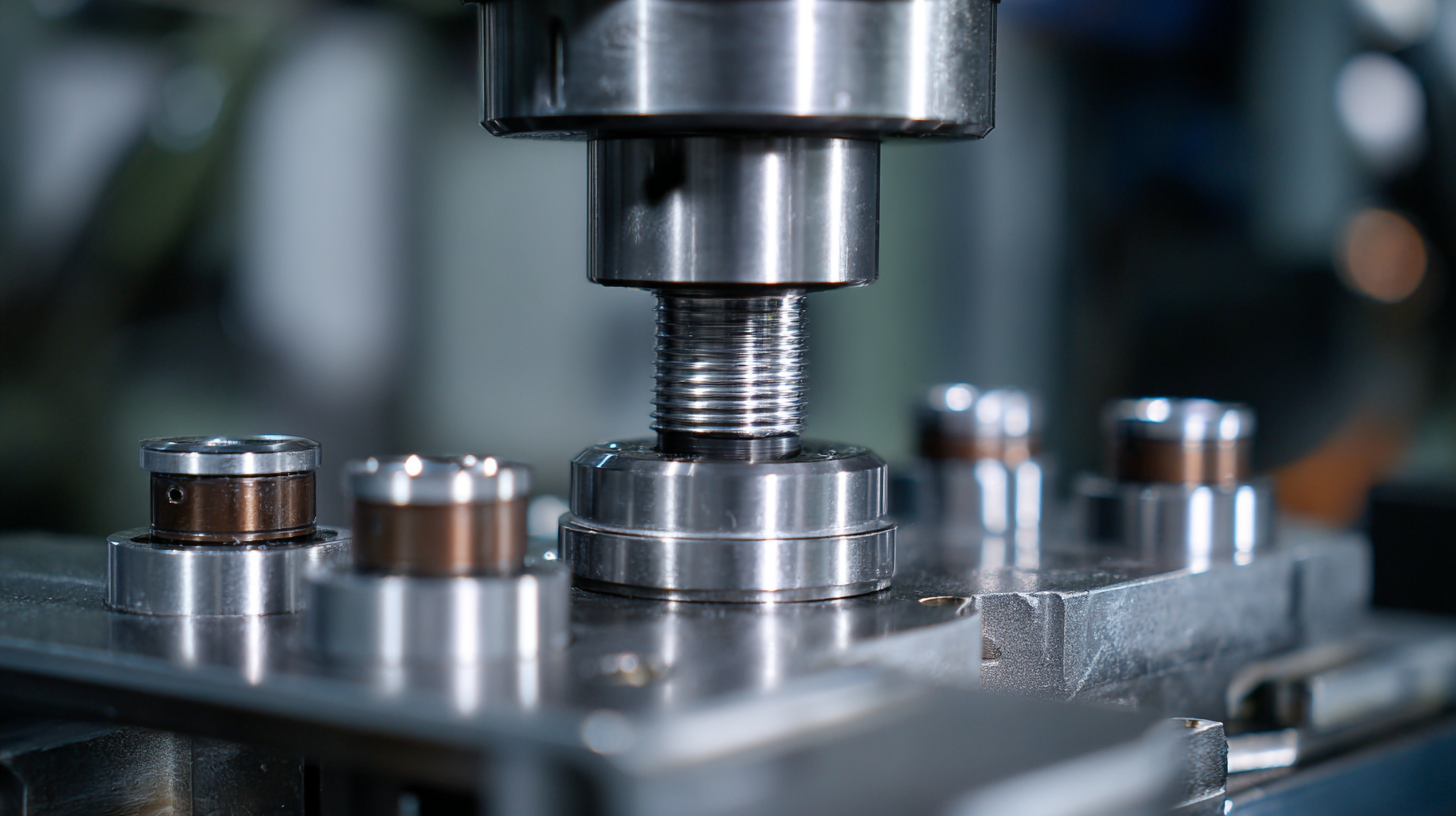

When selecting tapping machine collets, the material options play a crucial role in determining machining efficiency and overall performance. Common materials used for collets include steel, aluminum, and composite polymers, each offering distinct advantages. According to a report by the American Society of Mechanical Engineers (ASME), steel collets are favored for their durability and high tensile strength, making them ideal for heavy-duty applications. Steel collets typically provide better rigidity, which is essential for maintaining precise tolerances during tapping operations.

On the other hand, aluminum collets are known for their lightweight properties and thermal conductivity, enhancing speed and efficiency in machining processes. A study by the Society of Manufacturing Engineers (SME) indicated that using aluminum collets can reduce cycle times by up to 15% due to their faster heat dissipation, which minimizes deformation during operation. Additionally, advanced composite materials are gaining traction, offering a balanced combination of lightweight and strength. These materials can significantly reduce tool wear and fatigue, ultimately leading to extended lifespans for both the collets and tapping tools. Choosing the right material for collets not only optimizes machining performance but also contributes to cost-effectiveness in production environments.

| Material Type | Heat Resistance | Durability | Cost | Best For |

|---|---|---|---|---|

| Steel | High | Very Durable | Medium | General Purpose Machining |

| Aluminum | Medium | Moderately Durable | Low | Lightweight Applications |

| Carbide | Very High | Extremely Durable | High | Precision Machining |

| Plastic | Low | Low Durability | Very Low | Low-Stress Applications |

| Bronze | Medium | Moderately Durable | Medium | Corrosive Environments |

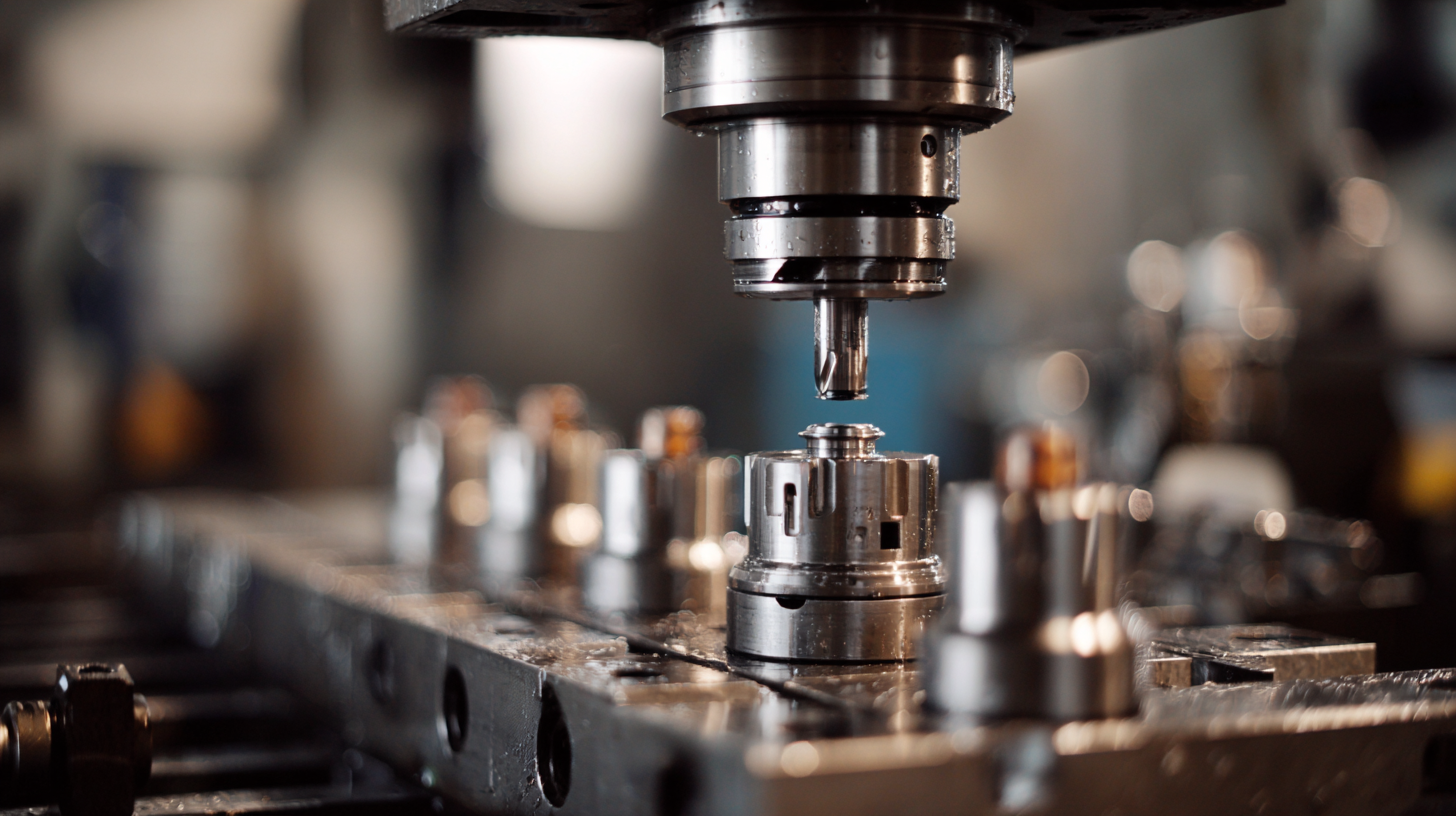

When matching tapping machine collets with specific tooling needs, it's essential to consider the material and geometry of the collet, as these factors significantly impact the machining efficiency. According to a 2022 market report by Grand View Research, the global demand for tapping machines is projected to grow by over 5% annually. This rising need emphasizes the importance of selecting the right collet, as improper choices can lead to increased wear and tear, affecting production quality and speed.

Different materials such as carbide and steel can alter performance. For instance, carbide collets offer superior durability for high-speed applications, while steel collets are often more cost-effective for low to medium-speed operations. Furthermore, ensuring that the collet's clamping range aligns with the tooling diameter is crucial; incorrect sizing can lead to slippage and damage. A study published in the Journal of Manufacturing Processes highlighted that optimizing collet selection can increase machining accuracy by over 20%, demonstrating the direct correlation between tool compatibility and overall productivity. Thus, understanding specific applications allows operators to enhance efficiency and extend the lifespan of both the collets and the tapping machines.

When selecting tapping machine collets, maintaining and optimizing their performance is crucial for ensuring longevity and operational efficiency. Proper maintenance not only extends the lifespan of collets but also improves machining accuracy. Recent advancements in collet technology, such as segmented collet designs, are tailored to enhance clamping for cylindrical and bevel gear bores, reflecting a growing trend towards precision engineering in the manufacturing sector. Data from industry reports indicate that the right collet can increase machining efficiency by up to 25%, emphasizing the importance of appropriate selection and care.

To keep tapping machine collets in prime condition, it is essential to adhere to best practices in maintenance. Common issues can arise from improper handling and misuse, as evidenced by a recent study identifying five prevalent mistakes associated with collet usage. These include failing to clean collets regularly, which can lead to diminished gripping power and inaccuracies during operation. Implementing a routine check for wear and tear, and using dedicated cleaning agents can significantly improve the performance and lifespan of these critical components. With the demand for ultra-precision manufacturing on the rise, proper maintenance protocols will help avoid costly downtime and ensure consistent production quality.