- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

A Toolholder Collet is an essential component in machining, serving as a precision clamping device for holding tools securely in various equipment, such as lathes and milling machines. Understanding the significance of a Toolholder Collet is crucial for machinists and engineers alike, as it directly influences the accuracy and efficiency of manufacturing processes. With a wide range of collet types available, each designed to cater to specific applications and materials, the decision of which collet to use can greatly affect the outcome of machining tasks.

The versatility of Toolholder Collets extends to multiple industries, including aerospace, automotive, and general manufacturing. By providing stability and reducing vibration during operations, these collets enhance the overall performance of cutting tools. Furthermore, the customization options available for Toolholder Collets ensure compatibility with various tools and machines, enabling a more tailored approach to machining challenges. This introduction to Toolholder Collets aims to explore its types, applications, and the critical role it plays in achieving precision in production environments.

A toolholder collet is a crucial component in machining operations, designed to secure cutting tools with precision. Its primary function is to clamp the tool tightly to prevent any movement during machining, which is essential for maintaining accuracy and achieving desired specifications. The design of collets allows them to evenly distribute clamping force around the tool shank, minimizing the risks of tool slippage and ensuring optimal performance.

According to a report by MarketsandMarkets, the global toolholding market is expected to reach $4.3 billion by 2025, indicating the growing importance of precision toolholding solutions, where collets play a significant role.

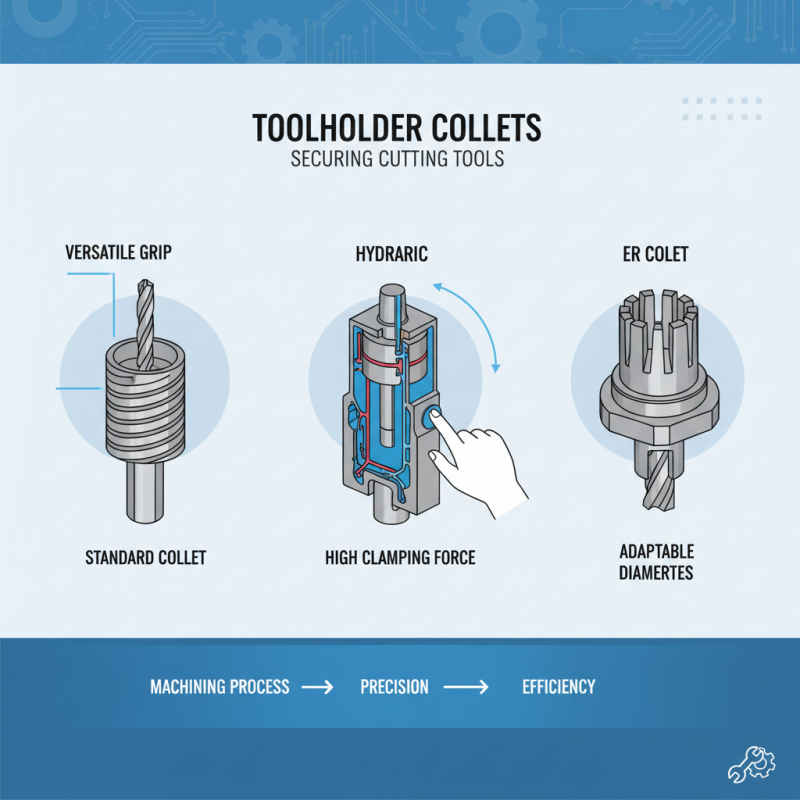

There are several types of toolholder collets, including standard collets, tapered collets, and quick-change collets, each serving distinct applications across various machining processes.

Standard collets are widely used for their versatility and ease of use, particularly in applications requiring quick tool changes without sacrificing accuracy. Tapered collets, on the other hand, are favored in high-speed milling operations, where enhanced stability and gripping strength are required.

A study by Grand View Research highlighted that the demand for high-precision machining components continues to grow, influencing the development of more advanced collet designs that cater to the needs of modern manufacturing environments. Tools that incorporate these advanced collet systems can enhance productivity and reduce downtime, ultimately driving efficiency in production lines.

Toolholder collets are essential components in various machining applications, serving to secure cutting tools in place during the manufacturing process. They come in a variety of types, each designed for specific functions and tool geometries. The most common types include the standard collet, which fits a wide range of tool shanks, and the hydraulic collet that provides enhanced clamping force through hydraulic pressure. Another significant type is the ER collet, known for its versatility and ability to hold tools with varying diameters due to its split design.

Each type of collet possesses unique characteristics catering to different machining needs. For instance, the standard collet is favored for its ease of use and quick tool changes, making it ideal for general machining tasks. On the other hand, hydraulic collets are preferred for high-precision applications where minimal runout is critical, as they provide better grip and stability under load. Similarly, ER collets are commonly used in CNC applications for their flexibility, accommodating a range of tool sizes while ensuring a secure fit during operation. Understanding these types and their specific capabilities can significantly enhance tool performance and machining efficiency.

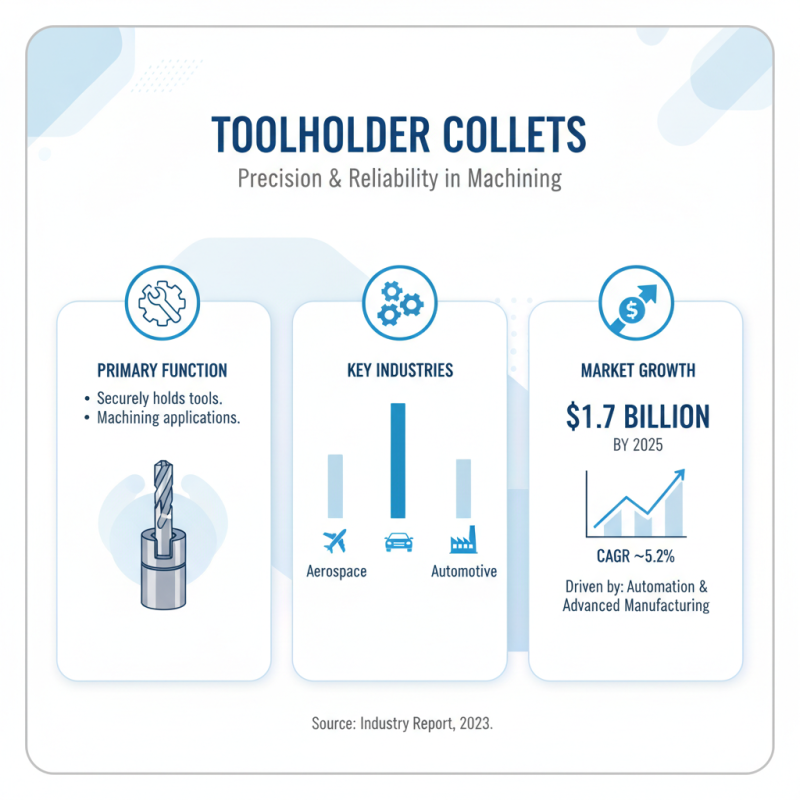

Toolholder collets are essential components widely used across various industries, serving the primary function of securely holding tools in machining applications. Their significance can be particularly noted in sectors such as aerospace, automotive, and manufacturing, where precision and reliability are paramount. According to a recent industry report, the global toolholder market is expected to reach approximately $1.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 5.2%. This growth is largely attributed to the increasing demand for advanced manufacturing techniques and automation in production processes.

In the aerospace industry, toolholder collets are utilized for high-speed machining of complex components involved in aircraft construction. The aerospace sector's need for lightweight yet robust materials underlines the importance of using collets designed for precision clamping during machining operations. Similarly, in the automotive industry, collets facilitate the production of intricate engine parts and body components, ensuring high levels of accuracy which are vital for vehicle performance and safety. As reported by the International Organization of Motor Vehicle Manufacturers, the automotive sector is projected to grow significantly, emphasizing the demand for efficient toolholding solutions to keep up with production rates.

Moreover, in the manufacturing industry, toolholder collets are indispensable for CNC machines where consistency and repeatability are critical. Their design allows for quick changeovers, minimizing downtime, and enhancing operational efficiency. The ability to accommodate various tool sizes and types makes collets a versatile choice, especially in environments where versatility is crucial. As industries continue to evolve with technological advancements, the application of toolholder collets will play an increasingly vital role in fostering innovation and productivity.

The installation of toolholder collets is a critical process that directly affects machining accuracy and efficiency. To begin with, ensure that the collet is compatible with both the toolholder and the tool itself. Start by cleaning the collet and the holder to remove any debris or contaminants that could interfere with a secure grip. Position the collet within the holder, aligning it properly to avoid any misalignment that could lead to tool slippage during operation. Gradually tighten the collet using the appropriate mechanism (such as a drawbar or nut) to secure the tool firmly, while being careful not to overtighten, which might damage the components.

Maintaining toolholder collets is equally vital for optimal performance and longevity. Regular inspection for wear and tear, such as cracks or deformation, is essential to prevent unexpected failures. It's recommended to clean the collets periodically, using solvents that can dissolve built-up grease and metal particles. Additionally, applying a light coat of oil can help prevent rust and extend the life of the collet. When not in use, collets should be stored in a dry, clean environment to avoid contamination. By following these installation and maintenance tips, operators can ensure their collets perform reliably, enhancing overall machining productivity.

Toolholder collets play a pivotal role in precision machining by providing a reliable and efficient means to secure cutting tools and workpieces. One of the primary benefits of using collets is their ability to evenly distribute clamping force. This uniform pressure minimizes tool runout, which is crucial for maintaining tight tolerances and achieving superior surface finishes. As a result, precision machining operations can produce components that meet stringent specifications, enhancing overall productivity and quality.

Another advantage of toolholder collets is their versatility. They come in various sizes and designs, accommodating a wide range of tool diameters and shapes. This adaptability allows manufacturers to quickly switch between tools and workpieces without the need for extensive setup time. Additionally, since collets can securely hold tools at different lengths, they provide greater flexibility in machining operations. This flexibility not only optimizes workflow but also contributes to reduced downtime, ultimately leading to increased efficiency in production environments.