- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the rapidly evolving manufacturing landscape, the importance of precision engineering tools cannot be overstated, with the Universal Milling Head emerging as a pivotal component in achieving operational efficiency and product quality. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach $117.17 billion by 2026, growing at a CAGR of 6.0%. This growth underscores the increasing demand for versatile and high-performance milling solutions that adapt to diverse machining applications. As manufacturers strive to enhance productivity and reduce costs, selecting the right Universal Milling Head is essential for optimizing milling processes and ensuring dimensional accuracy in component fabrication. This ultimate guide will delve into key considerations and expert insights to help you make an informed decision tailored to your specific machining needs, paving the way for enhanced manufacturing capabilities in the competitive global market.

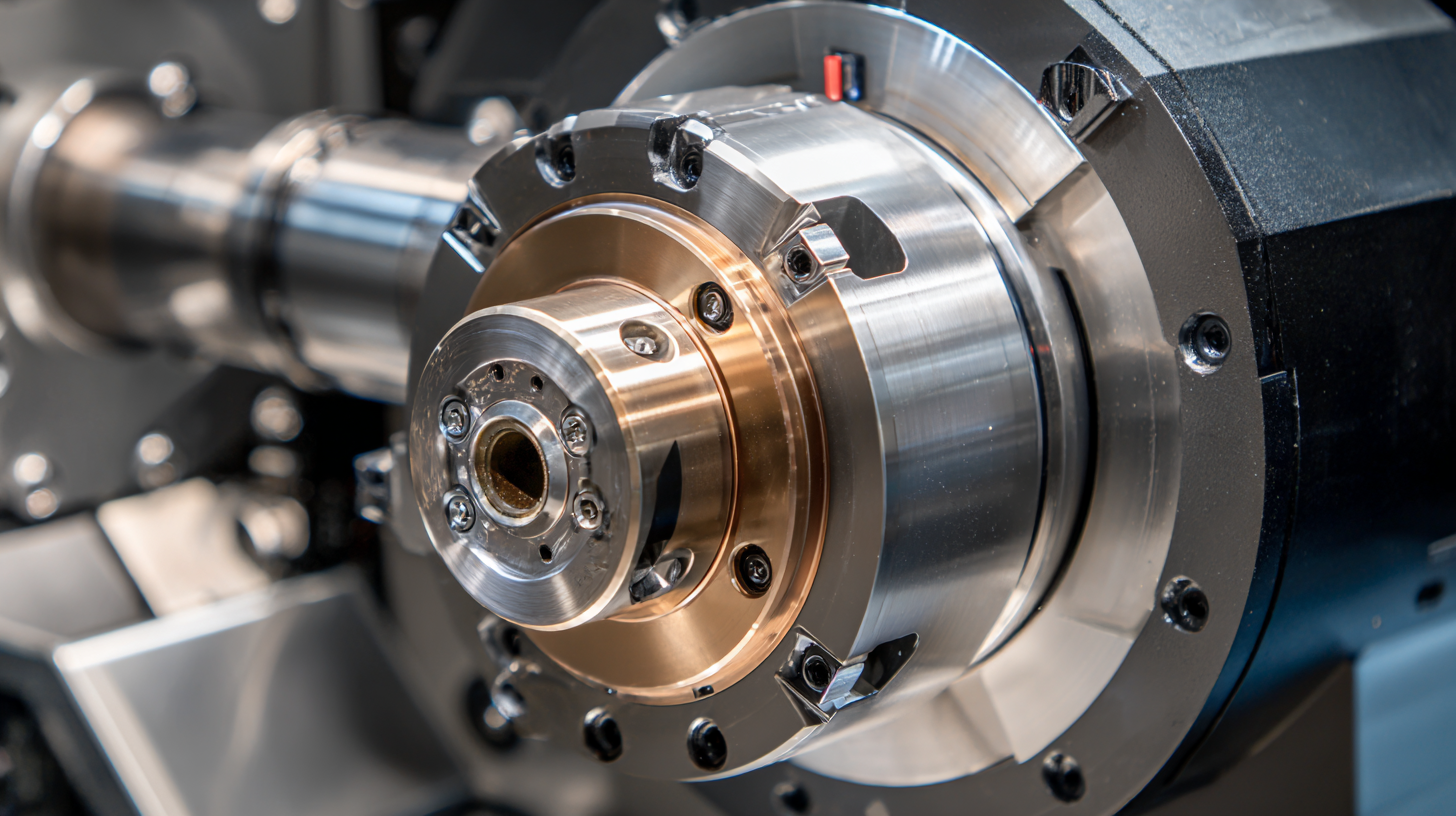

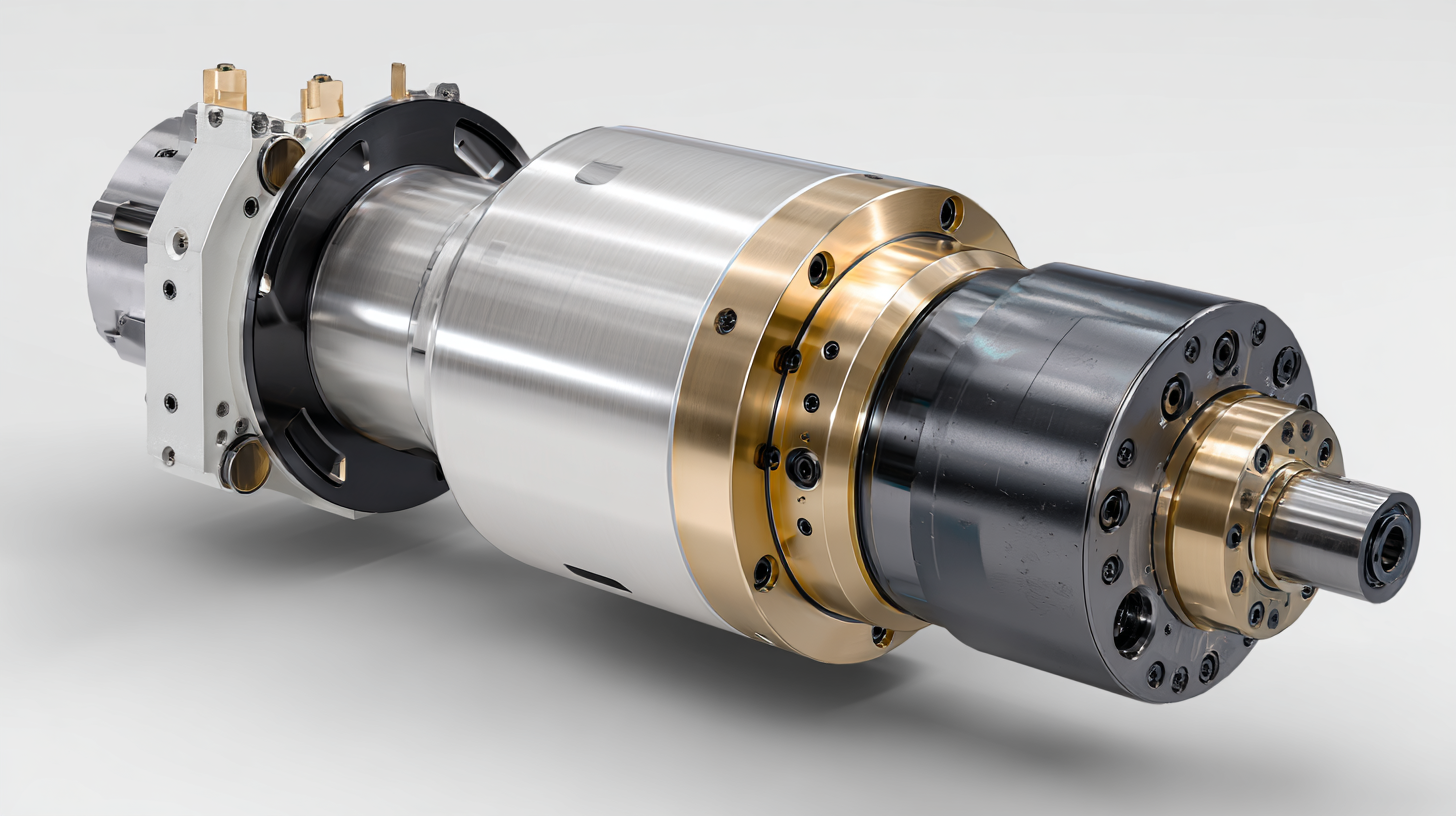

When selecting a universal milling head, it's crucial to understand key specifications and features that cater to your machining requirements. First, consider the milling head's compatibility with your existing machinery. Ensure that the mounting system aligns with your machine to avoid additional modifications. Additionally, examine the milling head's speed range and power capabilities. These factors play a significant role in determining the quality of the finished product and the efficiency of your operations.

Tips: Look for milling heads that offer variable speed settings, allowing versatility for different materials and cutting techniques. This capability can enhance productivity and precision.

Another important aspect to evaluate is the type of tooling that the universal milling head can accommodate. Different projects require various cutting tools, so a flexible head that supports a range of tool sizes and shapes can be a significant advantage. Finally, pay attention to the design and build quality of the milling head. A robust construction is essential for durability, especially in high-performance environments.

Tips: Opt for milling heads made from high-quality materials, as they tend to offer better wear resistance and longevity, ultimately leading to lower maintenance costs.

| Specification | Description | Importance |

|---|---|---|

| Spindle Speed | Measured in RPM, indicates the maximum rotational speed of the spindle. | Critical for determining the material types that can be worked on effectively. |

| Tool Holder Compatibility | Refers to the type of tool holders that the milling head can accommodate. | Important for ensuring that preferred tools can be used without issues. |

| Feed Rate | The speed at which the cutting tool moves through the material, typically in mm/min. | Essential for optimizing productivity and achieving desired finishes. |

| Weight | Total weight of the milling head, affecting stability and machine compatibility. | Affects the ease of handling and the setup of milling machines. |

| Tilt Angle | The angle at which the milling head can tilt, usually in degrees. | Valuable for performing complex machining operations. |

| Material Construction | Type of materials used in the construction of the milling head. | Influences durability, precision, and overall performance. |

When selecting a universal milling head, it's crucial to consider the impact of international certification standards on milling head performance. These standards, such as ISO 9001 and CE marking, help ensure that milling heads meet rigorous quality and safety requirements. According to a recent report by the International Organization for Standardization (ISO), equipment that adheres to these standards typically exhibits a 15% increase in operational efficiency and a 25% reduction in maintenance costs compared to non-certified counterparts. This evidence underscores the importance of choosing certified equipment that not only meets performance expectations but also supports long-term reliability.

Tip: Always verify that the milling head you consider is prominently marked with applicable international certifications. This can be a straightforward way to gauge its quality and overall reliability.

Additionally, certification often assures that manufacturers engage in continuous improvement practices. A study by Quality Digest revealed that companies investing in certified equipment report a 30% improvement in production consistency. Such standards also encompass material quality and precision manufacturing processes, which are vital for enhancing milling head durability and performance.

Tip: Consider the manufacturer's history with international certifications, as a robust track record can be indicative of sustained quality and technological advancement in their product offerings.

When selecting a universal milling head, the material is a crucial factor to consider. Steel, cast iron, and aluminum each present unique advantages and disadvantages. For instance, steel boasts remarkable strength and durability, making it ideal for heavy-duty applications, whereas cast iron provides excellent vibration dampening properties, which can enhance machining precision. Aluminum, on the other hand, is lightweight and corrosion-resistant, offering ease of handling and reduced wear on machinery.

Tip: Always evaluate the specific application requirements before making a material choice. For high-stress tasks, opt for steel or cast iron. Conversely, for lighter tasks and portability, aluminum might be the better choice.

Moreover, advancements in manufacturing technology have improved the performance characteristics of these materials. Recent trends indicate that while aluminum is growing in popularity, especially for cost-sensitive projects, iron components may provide superior strength, particularly for high-performance engine applications.

Tip: Consider the surface finish required for your milling operations. A smoother finish can significantly enhance sealing performance in applications like engine components. Proper surface treatment can optimize functionality whether you choose steel, cast iron, or aluminum.

The latest advancements in universal milling technology are paving the way for more capable and sustainable manufacturing processes. As industries increasingly seek to enhance productivity while minimizing their environmental footprint, innovations such as intelligent automation are becoming essential. For instance, the development of next-generation intelligent rack power distribution units showcases how automation can meet industry challenges effectively and economically.

Moreover, the integration of AI into universal milling heads reflects a significant shift towards smarter manufacturing. With brain-inspired designs, these innovations not only improve functionality but also address energy and resource efficiency. As we navigate this evolving landscape, it's crucial for manufacturers to consider how these technologies can enhance their capabilities while promoting sustainability. The exploration of these latest innovations highlights the potential for universal milling technology to transform industries, ultimately leading to greater efficiency and reduced environmental impact.

When it comes to importing and certifying a universal milling head for your business, the process can seem daunting, but breaking it down into manageable steps simplifies the journey.

First, it’s essential to conduct thorough research on the specific milling equipment that meets your operational needs. Consider factors such as the machine's capabilities, brand reputation, and customer reviews. This will help you narrow down your options and select a milling head that not only fits your modular requirements but also aligns with your production goals.

Once you’ve chosen the right milling head, the next step is to navigate the import regulations specific to your region. This includes understanding tariffs, customs documentation, and compliance with local standards. Engaging with a reliable freight forwarder can streamline this process, ensuring all paperwork is in order.

After successful import, certifying the machinery prior to use is crucial; this may involve inspections and compliance with safety regulations. Certification not only guarantees the quality and safety of the equipment but also enhances your business’s credibility in the manufacturing sector.