- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the realm of precision engineering, the advent of the Universal Angle Head has revolutionized manufacturing processes by enhancing versatility and accuracy. Recent industry reports indicate that the global precision engineering market is projected to reach $103 billion by 2025, with innovations like the Universal Angle Head contributing significantly to this growth.

This specialized tool enables machinists to achieve intricate angular positioning and optimize cutting angles, thereby improving both efficiency and product quality. According to a survey by the National Institute of Standards and Technology, 87% of machining professionals have reported time savings and enhanced production capabilities after incorporating Universal Angle Heads into their workflows. As we explore the secrets behind this transformative tool, it becomes evident that maximizing its potential is key to thriving in today’s competitive landscape.

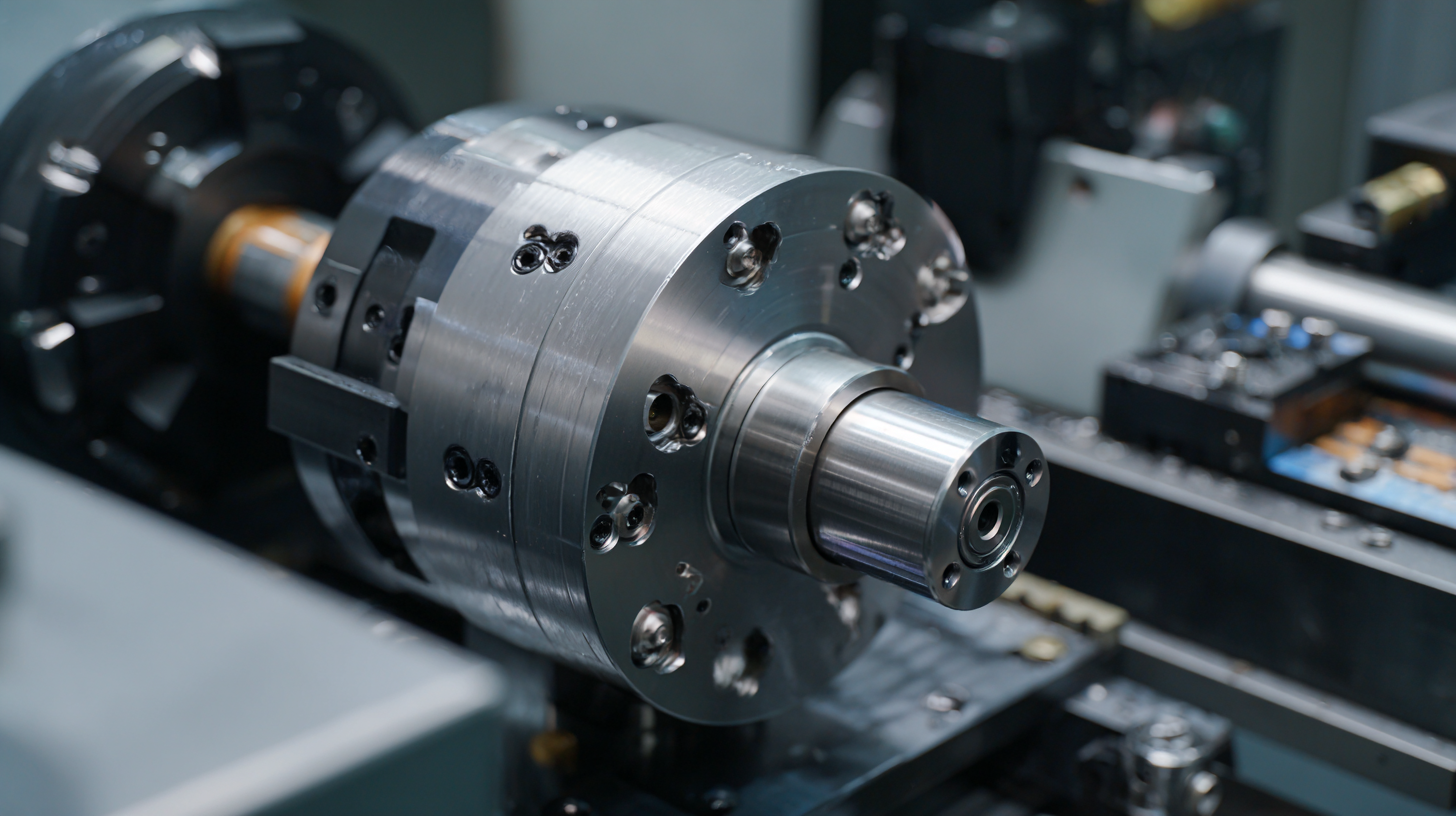

The universal angle head is an essential tool in precision engineering, designed to enhance machining flexibility and accuracy. Its primary function is to allow the spindle of a machine to operate at various angles, providing a significant advantage when tackling complex geometries and workpieces. This tool can be attached to milling machines, lathes, or CNC machines, transforming them into multi-functional systems that can perform various operations without the need for extensive repositioning or re-clamping of the workpiece.

By facilitating angular machining, the universal angle head minimizes setup time and reduces the risk of errors, ensuring that parts are manufactured to precise specifications. Its ability to accommodate different tool types also enables engineers to execute a wide range of operations, from drilling to contouring, with exceptional precision. As precision engineering continues to evolve, the universal angle head stands out as a transformative component that enhances efficiency, reduces waste, and allows for greater creativity in design and production processes.

The universal angle head is a revolutionary tool in precision engineering, significantly enhancing machining flexibility and accuracy. According to a report by Market Research Future, the global machine tool market is projected to reach USD 100 billion by 2025, with a substantial contribution from advancements in tooling technologies like universal angle heads. These tools allow for multiple machining angles without the need for repositioning the workpiece, thereby reducing cycle times and increasing overall productivity.

The universal angle head is a revolutionary tool in precision engineering, significantly enhancing machining flexibility and accuracy. According to a report by Market Research Future, the global machine tool market is projected to reach USD 100 billion by 2025, with a substantial contribution from advancements in tooling technologies like universal angle heads. These tools allow for multiple machining angles without the need for repositioning the workpiece, thereby reducing cycle times and increasing overall productivity.

One of the key benefits of universal angle heads is their ability to perform complex operations with exceptional accuracy. A study published by the International Journal of Advanced Manufacturing Technology reveals that integrating angle heads can improve machining accuracy by up to 30%. This is crucial in industries where precision is paramount, such as aerospace and automotive manufacturing. Additionally, by enabling multi-axis machining, these tools allow engineers to design components with intricate features that were previously difficult or impossible to achieve, pushing the boundaries of innovation in the field.

Furthermore, the flexibility offered by universal angle heads can lead to significant cost savings. With the ability to transition between different machining operations seamlessly, manufacturers can streamline their workflows and reduce the need for multiple setups. A report by Deloitte highlights that companies that adopt advanced milling technologies can experience a reduction in operational costs by as much as 20%, allowing for a more competitive edge in today's fast-paced market.

The universal angle head is an innovative tool in precision engineering that significantly enhances productivity in manufacturing processes. With the ability to manipulate tooling at various angles, operators can achieve optimal cutting positions without interrupting the workflow. This flexibility allows for more complex component shapes to be machined faster and with greater accuracy, ultimately leading to a notable improvement in overall efficiency.

Industry statistics indicate that the integration of universal angle heads can boost productivity by up to 40%. This remarkable increase not only accelerates production timelines but also reduces the operational costs associated with traditional machining setups. As businesses strive for greater efficiency, the adoption of such advanced technology becomes essential. In an era where automation and robotics are increasingly influencing manufacturing practices, investing in tools like universal angle heads aligns well with the broader trends of increasing productivity and enhancing operational effectiveness in the industry.

When choosing the right universal angle head for precision engineering, several critical factors must be taken into account to ensure optimal performance. The market for precision machining tools continues to evolve, with a recent report indicating that the global precision engineering market is expected to reach $1 trillion by 2025, driven primarily by advancements in manufacturing technologies and increasing demand for high-quality components. One of the pivotal elements in selecting an angle head is the tooling compatibility, which impacts the efficiency and precision of machining operations.

Professionals must consider the specifications of their existing machines and how the angle head's design complements their configurations.

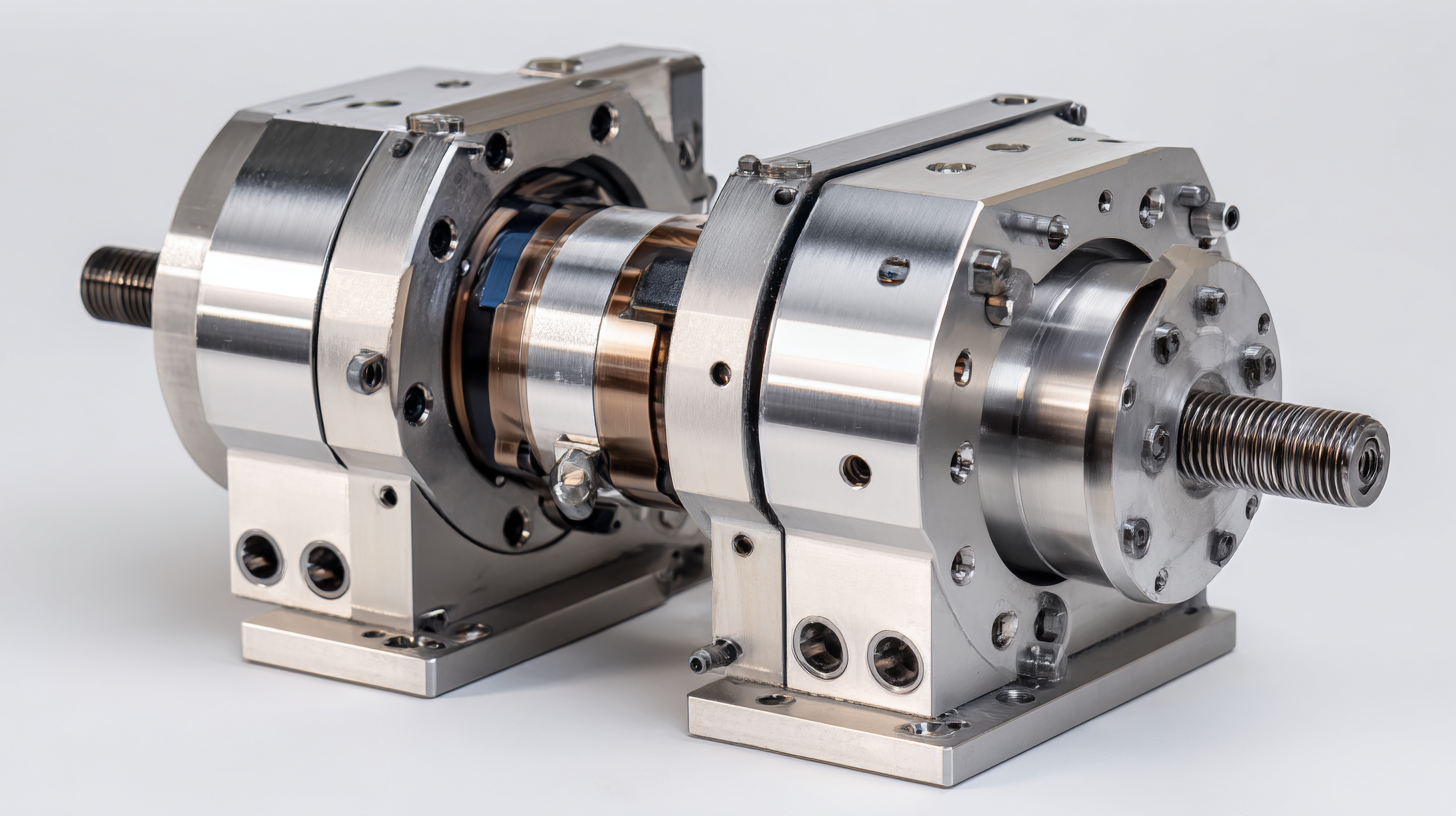

Another factor to consider is the material used in the angle head's construction. High-quality materials can significantly enhance durability and performance, particularly under demanding conditions. According to industry analyses, tools made from advanced alloys and composites demonstrate up to 30% greater longevity compared to their standard counterparts. Additionally, evaluating the angle head's gear ratio and speed capabilities is essential, as these characteristics can affect both the accuracy of the cut and the overall cycle time. This thorough evaluation of specifications and compatibility ensures that engineers can leverage the full potential of universal angle heads in their precision machining processes.

The universal angle head is revolutionizing precision engineering by introducing innovative designs that enhance versatility and efficiency in manufacturing processes. With the ability to adjust angles and orientations dynamically, these tools facilitate complex machining operations that were once tedious and time-consuming. Engineers and manufacturers are now able to reach intricate geometries with enhanced accuracy, reducing setup times and improving overall productivity.

Recent advancements in materials science and ergonomic design have led to lighter, more durable angle heads that can withstand the rigorous demands of modern engineering applications. Innovations such as quick-change systems and integrated cooling mechanisms further amplify their effectiveness, allowing for seamless transitions between different machining tasks. As industries strive for higher efficiency and precision, these transformative technologies are setting new standards, ensuring that the future of engineering is not only more streamlined but also capable of meeting increasingly complex challenges.