0102030405

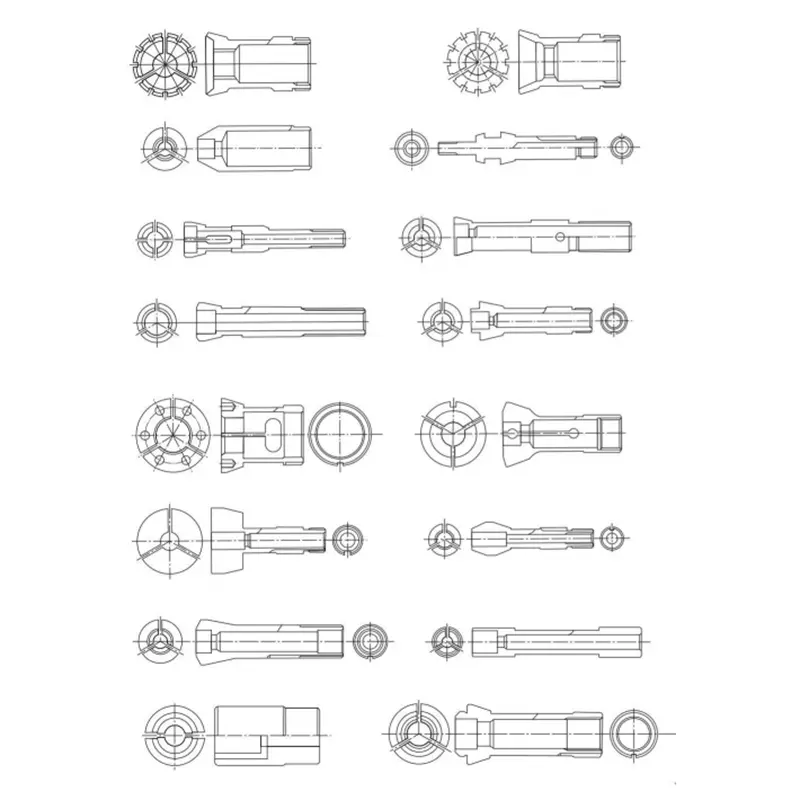

Multi-spindletapping Machine Collets

Products Parameters

| Boring | ||||||

| Model No. | ΦD Tool shank | ΦDmm | Lmm | M | H(mm) | Clamping size (mm) |

| C-4 | Φ1-Φ4 | Φ8.2 | 24 | 1/4-28UNF | 6 | Φ4 |

| C-5 | Φ1-Φ5 | Φ10.8 | 31.5 | 5/16-24UNF | 8 | Φ5 |

| C-6 | Φ1-Φ6 | Φ13.1 | 36.0 | 3/8-24UNF | 10 | Φ6 |

| C-9 | Φ1-Φ9 | Φ17 | 46.0 | 1/2-20UNF | 14 | Φ9 |

| C-12 | Φ2-Φ12 | Φ21 | 50.0 | 5/8-18UNF | 17 | Φ12 |

| C-14 | Φ5-Φ14 | Φ24.5 | 54.0 | 3/4-16UNF | 21 | Φ14 |

| C-16 | Φ5-Φ16 | Φ31 | 70.0 | M24-2.0 | 26 | Φ16 |

| Tapping | ||||||

| Model No. | ΦD Tool shank | ΦDmm | Lmm | M | H(mm) | Clamping size (mm) |

| CT-4 | Φ3-Φ4 | Φ8.2 | 24 | 1/4-28UNF | 6 | M3.5x0.16 |

| CT-5 | Φ3-Φ5.5 | Φ10.8 | 31.5 | 5/16-24UNF | 8 | M4x0.7 |

| CT-6 | Φ3-Φ6 | Φ13.1 | 36 | 3/8-24UNF | 10 | M6x 1.0 |

| CT-9 | Φ3-Φ7 | Φ17 | 46 | 1/2-20UNF | 14 | M8x1.25 |

| CT-12 | Φ3-Φ9 | Φ21 | 50 | 5/8-18UNF | 17 | M12x1.75 |

| CT-14 | Φ3-Φ12 | Φ24.5 | 54 | 3/4-16UNF | 21 | M14x2.0 |

| CT-16 | Φ3-Φ14 | Φ31 | 70 | M24-2.0 | 26 | M18x2.5 |

BOD collets

Collets are the holding devices of Tool or Raw materials or Components while machining and other operations.

The Dead length Collets are used on Main and Rear Spindles in many turning machines like Cam operated lathes like Tornos, Strohm, Bechler, Traub and CNC Swiss automatic lathes like Citizen-Cincom, Tornos, Star, Tsugami, Hanwha, Nexturn, Nomura, KSI-Swiss, Ge-Fong, Goodway, Wivia, Poly GIM, Swiss-Tek, Manurhin, Eurotech, Doosan and Maier machines to name a few. There are many other machines that uses Tecnicrafts Collets for various machining applications.

Collets made of High-quality spring steel

Tecnicrafts Collets are made of High-quality spring steel from renowned steel manufacturers and are machined and heat treated with inhouse Hardening and Tempering furnaces to obtain homogeneous grain structure and optimum spring qualities like Hardness, better Springing and strength, Wear resistance.

There is various type of Collets like ER collet, Dead length collets, Draw in Collets Push type collets, etc.

Why Choose Us

● Made from quality steels, carbides

● Faster Delivery

● Strong Customer Support

● High Quality and Precision

● Quality driven process and control

● All processes and facilities under one roof

● Dedicated/Skilled Manpower

● Customised Solutions

Quality Control

* We have specialized QC testers to check the quality of the products according to different customers' requirement.

* We have IQC to check the dimensions and surface of the incoming material.

* We have PQC to inspect full-course during the manufacturing processing.

* We have FQC to inspect all the anodizing/plating and other finishes' products from our supplier and proceed with the professional quality and appearance inspection before shipping.